Amentum, a global engineering organisation, and Beast Code, a data aggregation company, have formed a strategic partnership to deliver digital engineering solutions for the modernisation of the US Department of Defense’s (DoD) systems.

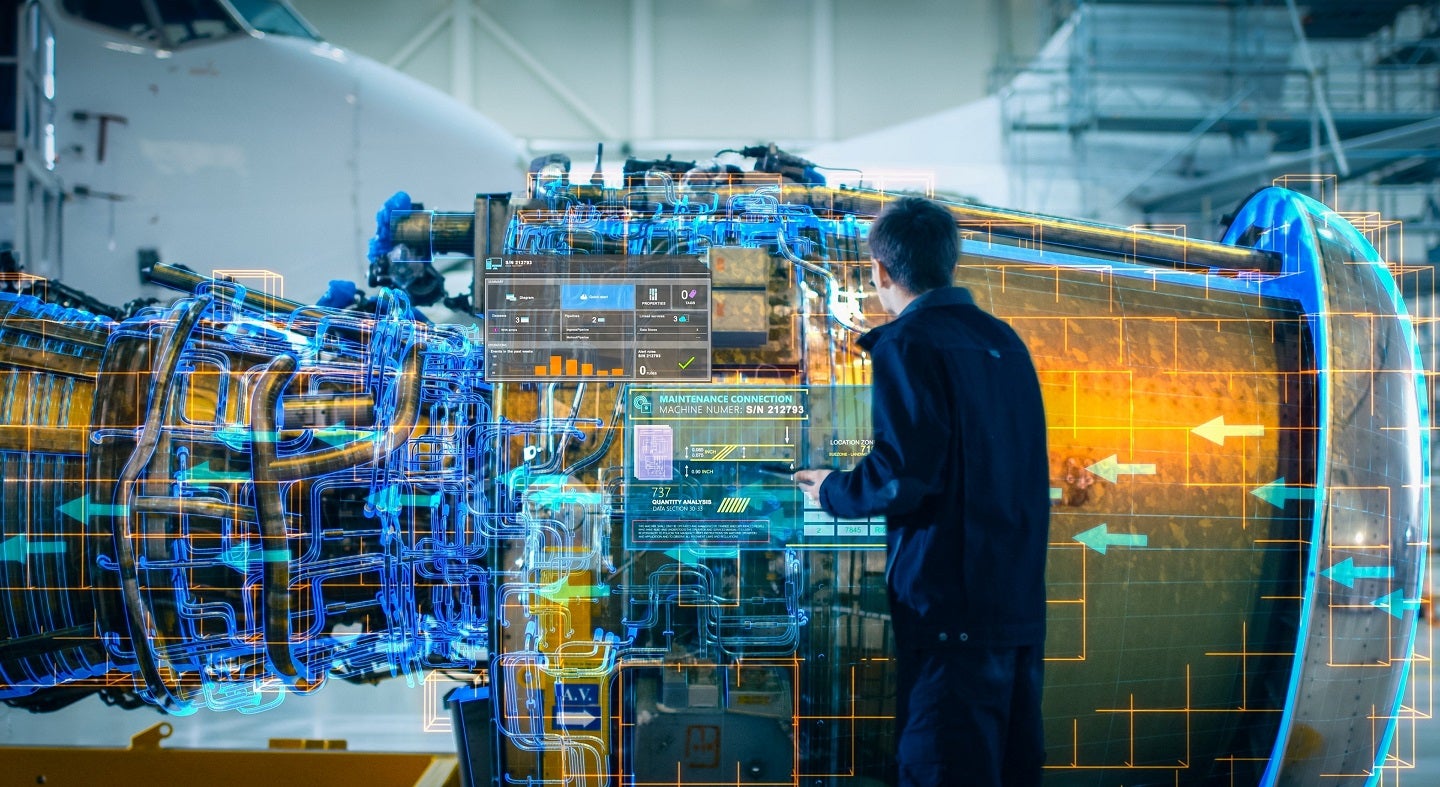

Digital twin technology replicates physical systems and has emerged as a useful tool for decision-making, optimisation and simulations across the federal government – including the defence, intelligence and civil sectors.

Beast Code’s software aggregates data from multiple disparate sources and presents the information through an immersive 3D digital twin.

This complements Amentum’s engineering end-to-end lifecycle solutions in digital engineering, C5ISR, research and development, infrastructure, platform modernisation, logistics, training, data analytics and cybersecurity.

The DoD will leverage the two partners’ expertise for cost efficiency, agility and enhanced performance for all its systems.

“The technology will now give our US customers the ability to convert systems anywhere in the full life cycle to a native digital environment,” said Jill Bruning, President of the Engineering, Science and Technology Group. “This means the federal government can harness the power of digitalisation and achieve cost efficiency, agility and enhanced performance for all systems—whether they are still in the RDT&E phase or in sustainment.”

Digital in defence industry

The defence industry is already using digital twinning tech to design, troubleshoot and enhance concepts for systems. This risk-free method is a growing technique for defence companies trying to meet the new consumer demands that the war in Ukraine and the US-China rivalry have introduced.

MBDA UK is one European example, as it leverages its Digital Battlespace Facility, which has become fully operational this year. The facility will allow MBDA to market its wide range and diversely complementary products by showcasing the interoperability and interactions of different systems. The digital space demonstrates the weapons and platforms that can work together – no system is procured in isolation.

Likewise, Lockheed Martin has successfully validated its subsystem design for its middle defence interceptor, which will be used by the US Army. Currently, the interceptor programme is on track for its next major review. The digital engineering tools have hurried the process of research and development – eliminating the cost and time it takes to conduct real-world testing.