Panasonic Connect has produced its most robust variant in its line of TOUGHBOOK computers. The ‘TOUGHBOOK 40’ is the latest commercial off-the-shelf computer, and there are already signs that it will hit the ground running in the defence sector – all without a scratch.

Armed forces across Europe have expressed interest in the new variant, as many are inquiring into the computer’s specific capabilities. The Italian Army are said to have made the first move to adopt the computer for their military operations.

The Italian Army has a history as a consumer of Panasonic’s legacy products, such as the Panasonic CF 54 Portable computer. Building on their historical usage, the armed force in Nato’s southern flank is a natural place to start demonstrating the capabilities of the TOUGHBOOK 40.

During an exclusive event at Panasonic’s European factory hub in Cardiff, Army Technology toured the facility to find out more about the company’s manufacturing process.

Manufacturing the TOUGHBOOK 40

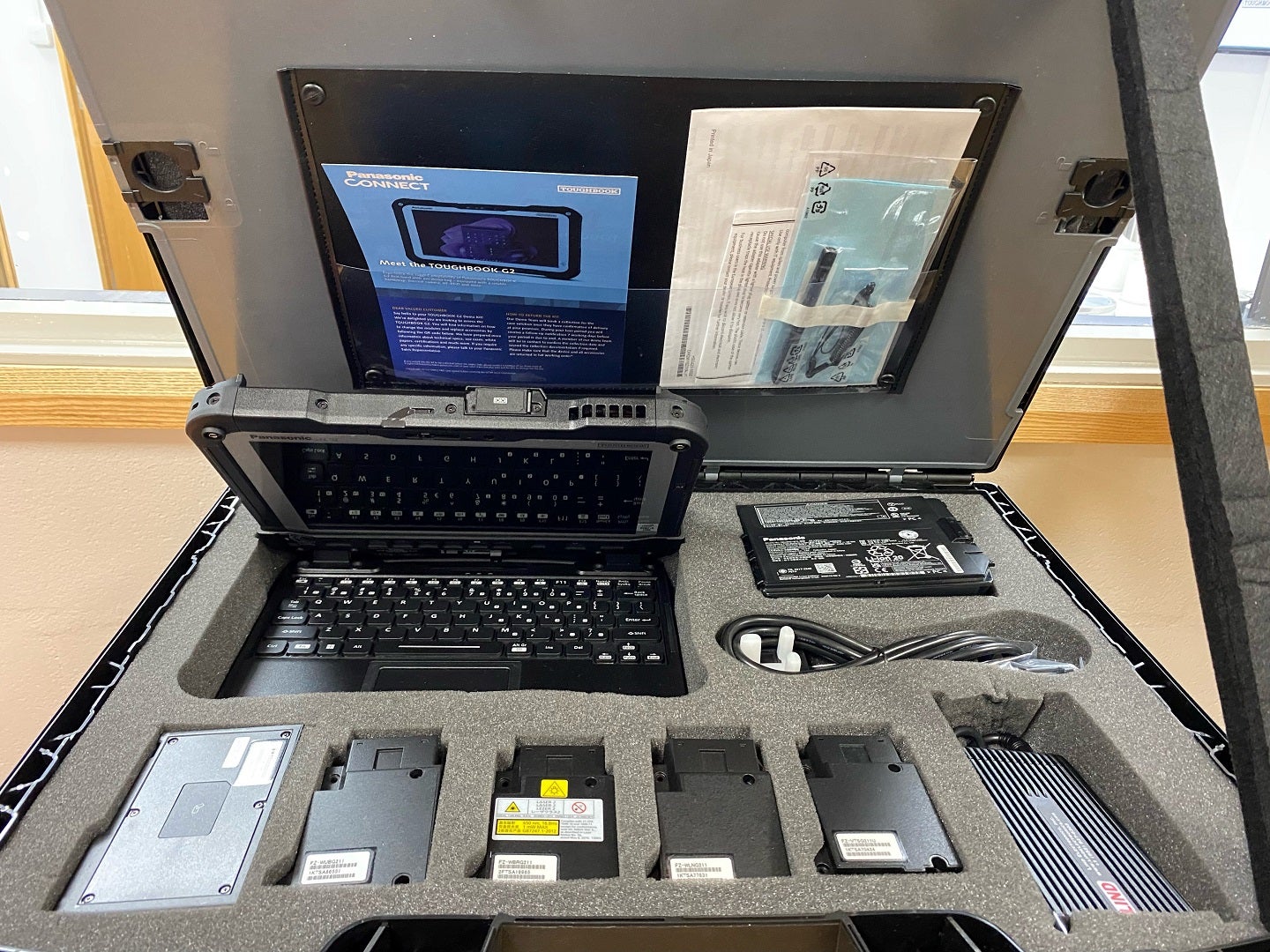

The TOUCHBOOK 40 offers the military end-user a range of benefits. The resilience of its hardware is the most notable as it is able to withstand the elements in the harshest environments around the world.

In fact, Panasonic Connect has ambitious testing standards to offer the most resilient computer notebook in the defence market. The company claims to use one single TOUCHBOOK 40 device across a range of different physical resilience tests, from withstanding harsh temperatures to severe vibration tests.

This contrasts with the standard practice of using a different device for every test, which testifies to the robust materials the company uses, such as its magnesium alloy components.

Around 70% of every TOUGHBOOK is assembled in Panasonic facilities in Osaka, Japan and Taipei, Taiwan, while the remaining 30% of each device is configured at the company’s Cardiff facility.

The TOUCHBOOK 40 undergoes a rigorous process of development by specialist engineers. This is reflected in the manufacturing quality regulations. One internal regulation brings production to a standstill if three or more devices exhibit failures of any kind, until such time as the issue has been resolved.

This quality-focus has brought about striking results. The Cardiff facility registered 0.06% anomalous failures in its production last year. This testifies to the balance of human precision and their semi-automated quality control system in the development process.

Lifetime support

The company also provides the end-user with an impressive wealth of support that justifies the company’s consideration of its latest computer as an “experience”; which is more than just a useful command and control (C2) tool in the battlespace.

Beyond the frontline benefits, armed forces will enter an experience that will sustain the product throughout its 7-10 year lifetime and beyond. Panasonic Connect offer persistent services for their TOUGHBOOK devices.

In-built quality controls see Panasonic operators perform a hybrid configuration development, marrying human precision with a semi-automated quality control system. This is a useful facet of production that allows the company to recall the process of development, which offers specific insight into every single aspect of each TOUGHBOOK device.

Panasonic Connect also offer training options for armed services, which may be reluctant to provide their solid-state drives (SSD) with sensitive information. These training schemes offer military services the ability to sustain their devices for various operations by becoming intrinsically aware of the computer’s vast amount of modular capabilities.