Donaldson Company is a leading worldwide manufacturer of filtration systems and replacement parts. Donaldson’s Aerospace & Defense Group, a division of Donaldson Company, is a leading worldwide provider of filtration systems for the aerospace and defense industry. Our filtration solutions protect fixed-wing aircraft, rotorcraft, military ground vehicles, electronic equipment, missiles, military shipboard systems and amphibious vehicles. We are committed to advancing filtration technology and providing quality products and prompt, knowledgeable customer service.

Donaldson began manufacturing and supplying filtration products for the military during World War I. We have an established, dedicated team to provide the special expertise and experience required for defense and military applications. Donaldson’s has more than a decade of experience in precision engineering, innovative design, on-site quality testing and for aggressively meeting military requirements, has continued to win our company a position as the premier filtration supplier for defense industries worldwide.

We specialize in custom design. Our prototype filter media manufacturing facility is cutting-edge, allowing us to develop and test media formulations that suit every filtration problem. Depending on each application’s requirements, we can choose from, and test, a wide assortment of media materials — including cellulose, polymeric, glass, fire retardant and electrostatically-charged media.

Donaldson is the ultimate filtration resource with technology including Ultra-Web® Nanofiber Technology, PowerCore®, Pulse Jet Air Cleaner (PJAC™) and PJAC Ultra® Systems, Inertial Particle Separator (IPS) Systems with Strata® Tubes, liquid filters – lube oil, coolant, fuel, transmission filtration, hydraulic manifolds, emission and exhaust systems, and Synteq XPTM patented media.

When you want the best protection for your military equipment from dirt and contaminants, bring Donaldson your main battle tanks, armored wheeled and tracked vehicles, amphibious vehicles, light-all terrain vehicles, gensets and other sensitive electronics fixed and rotary-wing aircraft and ships.

Donaldson main engine air intake, hydraulic, fuel, oil, transmission filtration and environmental control systems are found in main battle tanks including the Abrams, Challenger, Leclerc and Merkava; armored vehicles such as the Bradley, Stryker, M113, MRAP, M/ATV, Warrior, CVR(T), Bulldog; the Paladin M109 self-propelled artillery, M88 Hercules recovery vehicle and Terrier combat engineer vehicle; and trucks ranging from the Logistics Vehicle System Replacement (LVSR), HEMTT and FMTV to the HET, Sherpa , HMMWV, and rotorcraft like the UH-60, CH53D/E, CH-53K, Bell UH-1H, Kiowa Warrior, and AH/MH-6 Little Bird.

Pulse Jet Air Cleaner (PJAC™) Ultra®

The Donaldson PJAC is a patented, self-cleaning air filter that cleans filter elements with short duration pulses of compressed air. Using Donaldson’s Ultra-Web® Nanofiber Filtration Technology, the PJAC provides the highest level of efficiency – 99.997+% – and has a filter life of greater than 200 hours when tested per MIL-PRF-62048. Lab and field tests have demonstrated that servicing is reduced to less than one-tenth compared to conventional air cleaners.

PowerCore® and Flexible Packaging

The filter media is formed into honeycomb shaped flutes sealed on alternate ends. The honeycomb structure is more rigid than traditional pleated filters and twice as much filter media can be packaged within a given amount of space. The configuration allows for three times the capacity of conventional filters, equal or better performance in 60% less space than a conventional air cleaner, and can be custom fit to confined spaces.

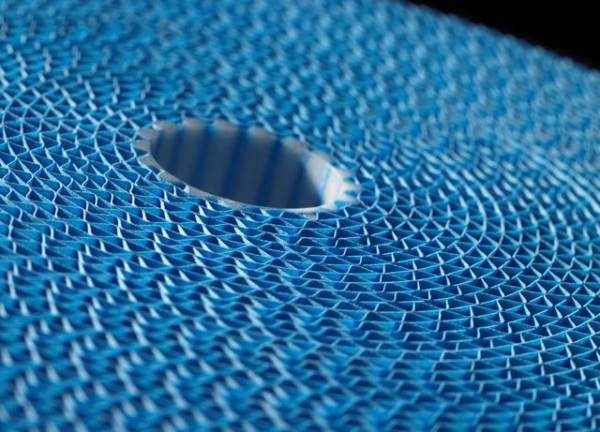

Ultra-Web® Nanofiber Technology

Nanofiber filtration causes sub-micron contaminant to load on the surface of a filter rather than dispersing throughout the depth of the filter media where there is less area for the air to flow. The smaller, interfiber spaces of Ultra-Web have higher filter efficiency and can hold up to five times more contaminants than cellulose filters – extending filter service intervals.

Synteq XP™

This patented media enhances system performance by increasing the filter’s efficiency, reducing operating pressure drop and extending the filter life up to three times that of a traditional cellulose filter.

Inertial Particle Separator (IPS) Systems with Strata® Tubes

Air particle separators with Donaldson’s specially designed Strata Tubes spin contaminants out of incoming air, providing reliable, minimal maintenance air filtration for every space requirement and performance level.

Debris

We’re focused on developing integrated solutions to meet regulatory emission standards around the world with products like Catalytic Convertor Mufflers (CCM) and Diesel Oxidation Catalysts (DOC). Our mufflers, silencers and exhaust systems reduce noise and back pressure, increase fuel economy and extend service life, whether you need a replacement muffler, total emission system design assistance, or are looking for ways to improve product performance and durability.

Liquid Filters – Lube Oil, Coolant, Fuel, Transmission and Hydraulic

Heavy-duty engines are built to last longer and to withstand more severe operating conditions. These improvements demand liquid filtration with design characteristics that optimize performance. Donaldson provides an extensive line of liquid filtration for main engine, APU and hydraulic systems. Our filtration ranges from filters to complex manifolds with indicators, valves and sampling ports.