How to ship high value equipment: A complete guide

At CP Cases we supply specialist protective gear across a huge range of industries, and the one thing that they all have in common is that they use highly specialised, sensitive and fragile equipment. From the medical and defence sectors to the broadcasting industry, only the most precisely designed and robustly constructed protection can ensure the consistent high performance of equipment in all settings.

However, the valuable and fragile nature of this equipment means that moving it around the world becomes a major logistical challenge. Here we explain exactly what you need to know and consider when shipping high-value equipment across the globe.

What can go wrong when shipping high-value equipment?

There are a number of different types of transit damage that can occur when high-value equipment is on the move. As soon as the product leaves your possession and is in the hands of the company shipping it, you need to know that it is sufficiently protected against any of these.

- Shock and impact, even from small bumps, can make highly specialised tools and equipment unusable

- Particular frequencies of vibration may damage sensitive equipment

- Static charges can make highly calibrated instruments unusable

- Any level of moisture, dust or dirt can damage sensitive electronics and may interfere with the circuitry that causes equipment to run effectively

- Extremes of temperature, humidity and changes in atmospheric pressure may all affect the performance of equipment

Having tailor-made protective cases, climate control units and specialised packaging in place can ensure that your equipment is protected from all of the above, completely sealed in its own microclimate.

Understanding the right type of protective casing for your equipment

We manufacture a huge range of protective cases, some of which come in standard sizes but many of which are designed to specification to meet exact requirements. This can make all the difference in keeping your equipment protected.

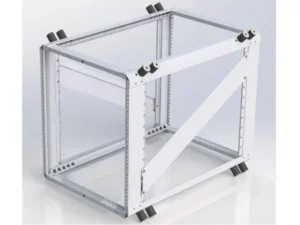

- 19-inch racks are used across a range of industries including defence and security. They allow for the safe transportation of fragile electronic equipment within checked baggage limits.

- Rugged textile cases can provide tailored padding for unusually shaped equipment, such as surgical tools or engineering gear while maintaining a lightweight

- Flight cases offer robust, heavy-duty protection for extremely fragile equipment like musical gear, made from plywood and strengthened with aluminium and steel

- Lightweight aluminium cases are widely used across the broadcast industry and can protect their contents against even severe impact

- Climate control transit cases can provide all-round protection from harsh weather, dust and dirt for any electronics, with insulation and air conditioning units fitted in order to prevent overheating.

Opting for aluminium casing can be an effective way to keep costs down if you are transporting something long-distance, but this does not necessarily apply for all types of equipment and some may require heavier casing.

Using inner foam to protect your equipment

Foam insert protection is the last line of defence for your equipment if the outside of a case is damaged. Used correctly, it completely isolates the item inside the case, protecting it from a collision with other objects in the same case and insulating it even the smallest vibrations or larger impacts such as that of the case being dropped. These types of outside impacts can damage sensitive equipment beyond repair, so simply placing it inside a case is not enough.

High-quality foam inserts can cope with repeated impact, are rigid enough to fully protect equipment and are soft enough to cushion it. It is also crucial that the foam can be precisely shaped to support every part of the equipment, and that any adverse effect on the equipment such as discolouration is not a possibility.

How to plan for successful shipping of equipment

In addition to the above, there are several practical steps that you can take in order to ensure that equipment is more likely to arrive at its destination in full working order.

- Undertake detailed and clear analysis of the environments that the equipment will pass through and the hazards it may face. How many times will it be handled?

- Assess risks which are specific to each item, whether in transit or otherwise

- Ensure that different types of packaging being used are compatible with one another

- Ensure, as best you can, that all staff involved in handling the equipment at each stage of the chain are aware of how to protect it correctly

- Work only with trusted and reputable transport providers

- Ensure that you have the correct insurance in place