DST Defence Service Tracks is a market leader in the maintenance and servicing of military vehicle fleets worldwide. Its highly trained and motivated workforce adheres to uncompromisingly high standards across the entire supply chain, from the production of raw materials until the finished product leaves the assembly line, and beyond.

Tradition alloyed with innovation

DST’s expertise extends to all main components on the running gears, such as tracks, road wheels, idler wheels and sprockets.

DST Tracks are used in vehicles on all continents and are characterised by an excellent terrain response, with all the components in the entire system being adjusted ideally to the respective areas of deployment.

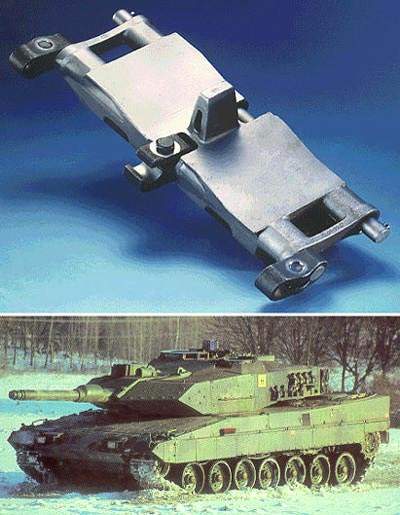

DST develops and produces more than 100 different tracks for all types of vehicles (Track OEM for MBT’s like Leopard 1 & 2, AIFVs like Marder, Puma, Pizarro and Ascod, APCs like the M113 family of vehicles, Artillery Systems such as the M109, PzH 2000 and others).

All tracked vehicles of the Bundeswehr and of almost all leading vehicle manufacturers around the world are fitted with DST tracks or running gear components.

Track Solutions

The iDST (iDeal System Track) and iDLT (iDeal Lightweight Track) reflect DST’s outstanding design capabilities and state-of-the-art technologies. The DST design and the double-pin track technology are a warrant for less torsion force, long service life, high-quality and reliability.

Proven long service life, maximum safety and a maintenance free track system are characteristics of DST’s outstanding track design. The iDLT is a lightweight design, which contributes to our customer demands for weight reduction to allow e.g. the installation of additional armour protection systems and to increase crew safety.

To contribute to the latest operational requirements, DST developed the iDBT (iDeal Band Track) system. Design objectives were weight reduction, noise and vibration reduction, and improvement of crew comfort.

The main feature of the iDBT is the patented segmentation (with connector), which in comparison to an endless band track, allows easy handling and replacement of track segments by the crew at any location.

The Quick-Fit® system

Initially developed for the MBT Leopard 1, Quick-Fit® is the patented system, with which individual track components can be assembled or replaced by a single engineer without the necessity for bolts or screws.

Continuous improvements and lighter materials have enabled DST to maintain their status as a market leader.

Protection

Today’s out-of-area operations and asymmetric warfare scenarios require the best possible crew protection. Together with partners and in close cooperation with the customer, DST designs holistic protection concepts for roof and mine protection.

The effectiveness of these solutions has been by the German Bundeswehr, with impressive results for overall concepts and individual components.

DST is considered to be the developer of tracks and the most important track manufacturer worldwide.

Performance enhanced by experience

Every technology has room for improvement. DST’s innovative maintenance strategies go far beyond simply repairing vehicles, offering a variety of service life extension options.

These solutions are designed to maximise vehicle efficiency and reliability, and are individually tailored to meet the requirements of our customers.

Maintenance

As one of the largest German Depot Level Facilities, DST provides a wide range of maintenance and support services for more than five decades, at its facilities in Freisen or on site at the customer’s location.

DST develops and implements maintenance and overhaul strategies including service life extension solutions.

Being independent of vehicle manufacturers, DST’s overhaul portfolio includes a wide range of wheeled and tracked vehicles including German Bundeswehr and the US-Army, along with NATO Allies and GCC countries such as:

- The German Army’s Marder

- M113

- Wiesel

- Fox

- Leopard 1 family

- Fennek

- Dingo

- Mungo

- Military trucks

- The US Army’s M113 family of vehicles

- M2 Bradley

- M9ACE

- HEMTT and HET trucks

DST is also certified as an Oshkosh service provider. As a single purpose facility, DST not only focuses on the vehicle platform but on all major assemblies and subassemblies, including engines, transmissions, final drives etc, which are subsequently overhauled and tested.

DST holds all necessary certificates and authorisations by major OEMs and government agencies to perform the relevant services.

As well as providing maintenance services, DST designed repowering solutions for the M109 howitzer of the UAE Land Forces, and was partner of the German Army’s Cooperative Maintenance Model HIL and the German Army’s Combat Training Center (GefÜbZH).

DST operates a dedicated in-field service team, which permanently supports the German Bundeswehr on site in Germany and the UAE Land Forces in Abu Dhabi.

Quality Assurance

DST holds all necessary quality assurance certificates for all iDeal Mobility Solutions.

Supply Chain Management

Supply chain management and logistic support systems are key factors for turn-around time, availability and life-cycle cost management.

DST operates a SAP-based ILS system including a comprehensive database, which is used to project and optimise current and future ILS and spare parts demand.

DST’s independent quality management organisation monitors conformity and efficiency of the quality system and procedures, along with its continuous improvement.