TeAx Technology, an innovative, trend-setting solution provider for thermal imaging technology within the global drone industry unveils another product: ThermalCapture Calibrator, which comes as an add-on. It compensates and strongly improves inconsistent absolute measurements caused by inherent limitations of internal shutters.

ThermalCapture Calibrator is designed for FLIR Tau 2 cores equipped with ThermalCapture 2.0 hardware and FLIR Vue Pro / R cores.

Enhance accuracy up to 70% with ThermalCapture Calibrator

“The global drone market more and more recognises the power of thermal data, captured by drone technology for further post-processing,” says Michael Thoss, VP Sales & Marketing of TeAx Technology.

“Companies such as DroneDeploy, PrecisionHawk or Service Providers, such as Sky Futures fully integrate radiometric thermal imaging technology for analyses and reporting and provide those as valuable data to big organisations and enterprises,” Thoss states.

He continues: “Now, all of those companies are using standard thermal cores. Under certain circumstances, like strong winds together with changes of camera orientation, or low surrounding temperatures, measurements can be affected by non-uniformities and limited absolute thermal accuracy. Those can lead to inconsistent, and sometimes wrong thermal datasets,” Thoss explains.

“However, we at TeAx are happy to announce our ThermalCapture Calibrator solution, which quite impressively improves thermal accuracy by up to 70%.”

Smart solution: An external, heated shutter

“Some of our clients reached the limits of what is possible with standard uncooled thermal cameras, if they are using them in challenging environments,” Stefan Thamke, CEO of TeAx Technology reflects. “As always, it was the feedback of our clients, which lead us into a phase of creative thinking on how we can improve those issues,” Thamke explains.

He continues: “Since we were aware of the capabilities of the internal shutter and the limitations that come with it, we quickly identified that the best solution approach is an external shutter.” In fact, studies of TeAx’ engineers lead into the concept for an external shutter. It provides all relevant information, that are needed to calibrate FLIR Tau focal plane arrays during runtime. The external shutter element is heated to provide an always accurate and uniform calibration target. As of today, that is the only way for professional drone operations, to create meaningful, consistent thermal datasets even within challenging environments.

Third party certification by independent auditors

“At TeAx Technology, consistency and accuracy are one of the core values, especially for any aspect of the quality of our work itself,” Stefan Thamke highlights. “In regards of the external shutter, we therefore want to highlight, that we work with independent third party calibration institutes, which confirm the accuracy of our thermal cameras.”

Clients of TeAx Technology can request an independent calibration certificate for their solutions.

Use case ‘thermal mapping’

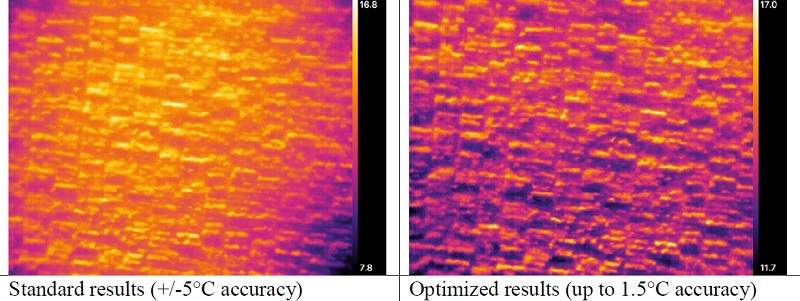

Stefan Thamke explains the main purpose for the external shutter: “In general, ThermalCapture Calibrator makes most sense for drone operators, who are in the need of creating thermal maps with consistent thermal data for absolute temperature measurement.” He further highlights: “If you were to achieve +/- 5°C accuracy with standard solutions, you now can achieve up to 1.5°C accuracy due to our ThermalCapture Calibrator.”

In fact, first beta tester for the External Shutter were very satisfied with the accomplished results: “We are using thermal cameras from TeAx Technology for agricultural researches with the goal of creating accurate, radiometric thermal maps,” explains Rainer Schlepphorst, from Forschungsinstitut für Bergbaufolgelandschaften e.V. in Germany.

“We were very satisfied with the solution by TeAx, but the thermal quality – especially in terms of accuracy – did not fully meet our expectations,” Schlepphorst stated further.

He continues: “When creating radiometric thermal maps, non-uniformities like cold corners in each thermal image, lead into inconsistent thermal data. Therefore we were not able to post-process as accurate as we intended to. That was the moment, when we contacted TeAx Technology again and asked for help.”

He sums up: “I was impressed how fast TeAx Technology developed a solution, which strongly increased our thermal measurements – we now have access to reliable and consistent thermal data, which allows us to create accurate thermal maps.”

For any enquiries or questions please call us on +49 2737 94042 60 or write an email to sales@teax.de