Armox® is a well-known high-end protection plate designed by SSAB to provide manufacturers of protection equipment with harder and tougher armour steel.

The Armox® brand is one of many steel grades from SSAB, a Swedish company specialising in quenched and tempered steels for protection, wear, structural and tooling applications.

Armox® grades from 300HBW to 600HBW and beyond

Armox® is delivered in a quenched and tempered condition, ready for processing and installation.

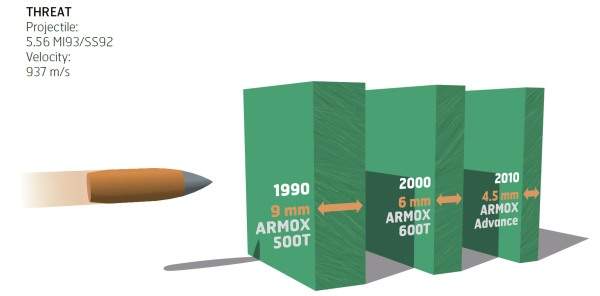

The standard Armox® grades are manufactured with a Brinell hardness from 300HBV to 600HBW and beyond. These grades have guaranteed mechanical properties for hardness, tensile strength and impact toughness. The plates range in thickness from 3mm to 150mm, depending on the selected grade.

SSAB also offers an ultra-high hardness ballistic grade, Armox® Advance. It has a guaranteed Rockwell C hardness of 58HRC to 63HRC. This grade comes in thicknesses from 4mm to 7.9mm and is intended for add-on armour applications.

Armor plates from SSAB for ultimate protection

Armox® provides ultimate protection in combination with ease of use in the workshop thanks to the steel’s relatively high toughness. Armox® grades are classified with protection levels according to several militaries and other standards for armour steel. They have been used to improve safety for people and property in the world’s most dangerous environments for more than 40 years. Armox® has quite literally been tested in the field.

SSAB also offers Ramor® protection steel, which is a direct-hardened steel with guaranteed hardness, good workshop properties, and excellent surface properties. It is primarily intended for civilian applications. Ramor® is produced in 300HBW to 600HBW hardness and is available as cut-to-length sheets or heavy plates in thicknesses from 2.2mm to 30mm, depending on the actual grade’s hardness.

Protection engineers and OEMs manufacturing protected vehicles or other vulnerable targets can tailor their designs by utilizing the wide portfolio of grades and dimensions for Armox® and Ramor®.

Quality control in every step

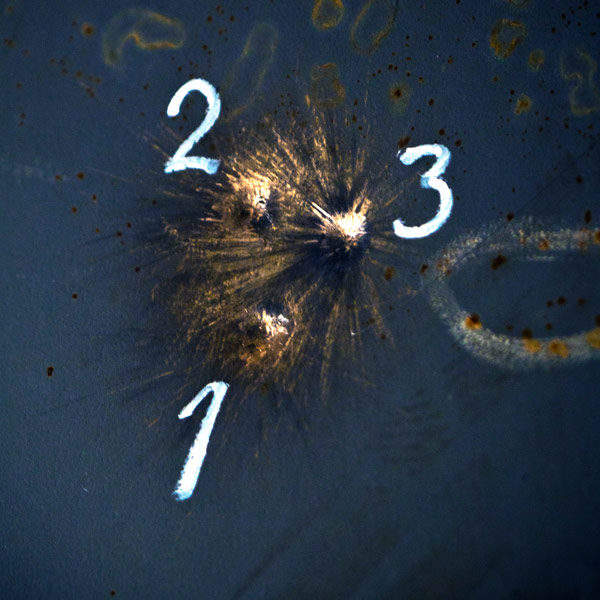

In addition to systematic quality checks at its own laboratories, SSAB collaborates with independent and internationally accredited centers for carrying out various ballistic tests. At SSAB, the entire production process is built to ensure all steel products leaving the factory match and exceed the international standards, conforming to customer specifications.

Protection with a sustainability edge

SSAB is in the process of phasing out its traditional steelmaking processes in favour of fossil-free technologies. This transformation applies to all SSAB steels, Armox® and Ramor® included. SSAB is already producing steel from two different sustainability concepts. One is based on HYBRIT technology, making SSAB Fossil-free™ steel with green hydrogen instead of coal and cok. The other concept, SSAB Zero™, is based on recycled steel produced with fossil-free energy.