ExploSpot Systems specialises in the development of fire and explosion suppression systems for the defence industry.

The company utilises lean and efficient manufacturing methodology and tools, enabling it to scale production while also being able to cater to client customisation requests.

Established in 1994, ExploSpot Systems is headquartered in Pretoria, South Africa, and has office locations worldwide, including in Egypt, Germany and Australia.

Automatic explosion suppression systems (AESS) for defence applications

Automatic explosion detection and suppression systems require an extremely reliable and fast detection and activation mechanism.

Not only will the optical detector developed and produced by ExploSpot Systems detect an explosion in two milliseconds (ms), but the suppression reaction will have started within 7ms–10ms depending on the distance between the suppression canisters and nozzle.

The unique double activation mechanism of ExploSpot Systems’ solution makes the activation of the suppression the most reliable on the market. The ultra-fast reaction of the system, combined with the appropriate suppression material, ensures that the temperature, pressure and toxic gas development remain below human tolerance levels.

This helps to ensure that military personnel survive an explosives attack on their vehicle such as by a shaped charge.

Innovative systems to protect soldiers against explosions and fires

The automatic explosion suppression solutions developed by ExploSpot Systems function as an automatic fire detection and suppression system. The combination is commonly called an automatic fire and explosion suppression system (AFESS).

These systems are unique as they will not only react immediately to the occurrence of a high-speed event such as an explosion, but they will also automatically and effectively react to a slow growing fire by suppressing the flames before they can damage the vehicle or injure personnel.

Military vehicle automatic engine fire detection and suppression

Pure automatic fire suppression systems are commonly used to detect and suppress fires in the engine compartment or auxiliary power unit (APU) of a vehicle.

ExploSpot Systems’ AESS only activate the suppression sequence when a characterised change of temperature state is detected. This ensures that the system is extremely robust and does not discharge the suppression material prematurely due to an unexpected ambient temperature rise.

The system is capable of redetecting a fire within six seconds of the first discharge, allowing for a reliable and safe multi-action suppression system.

Manual fire suppression system (MFSS) for wheeled armoured vehicles

All of ExploSpot Systems’ automatic fire suppression systems can cater for a manual override. In the case of a purely manually activated fire suppression system, the solution can only be activated by an operator within the vehicle or by utilising a switch located on the outside of a military vehicle.

These systems may also include optional functions such as the indication of overheating, as well as error detection and indication.

Manual fire suppression systems may be used on the wheels for wheel fire suppression, as well as on the external hull and roof of an armoured vehicle to increase vehicle survivability. Some military vehicles may also require a manual fire suppression system for the engine.

Real-time self-checking solution to monitor system errors

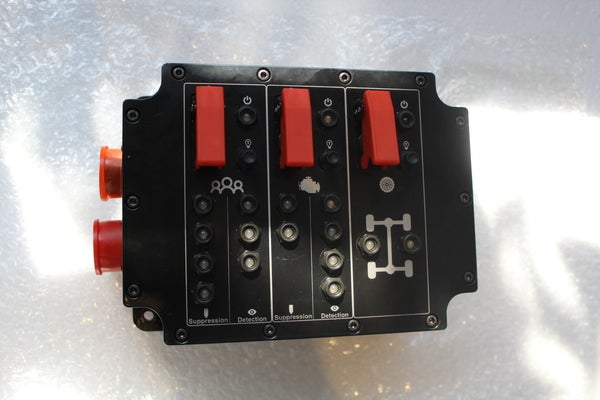

ExploSpot Systems’ automatic explosion suppression system is supplied with a real-time self-checking controller, meaning any electronic or pressure error will be indicated to the operator spontaneously.

All information is gathered from the system and displayed on the user interface, meaning all states and functions can be visualised and operated by the vehicle’s controller area network (CANBUS). The controller also allows for a power management system or auxiliary battery.

Easy-to-maintain explosion suppression systems for the defence industry

ExploSpot’s automatic explosion and/or fire suppression systems are free of BAFA and ITAR export regulations. Due to all patents and intellectual property being owned by ExploSpot Systems, localisation within a foreign country can easily be established.

In addition, ExploSpot suppression systems are easy to maintain, service and refill. There are no limitations on who (end-user, vehicle manufacturer, ExploSpot or a third-party) can take over the maintenance and service of these systems.