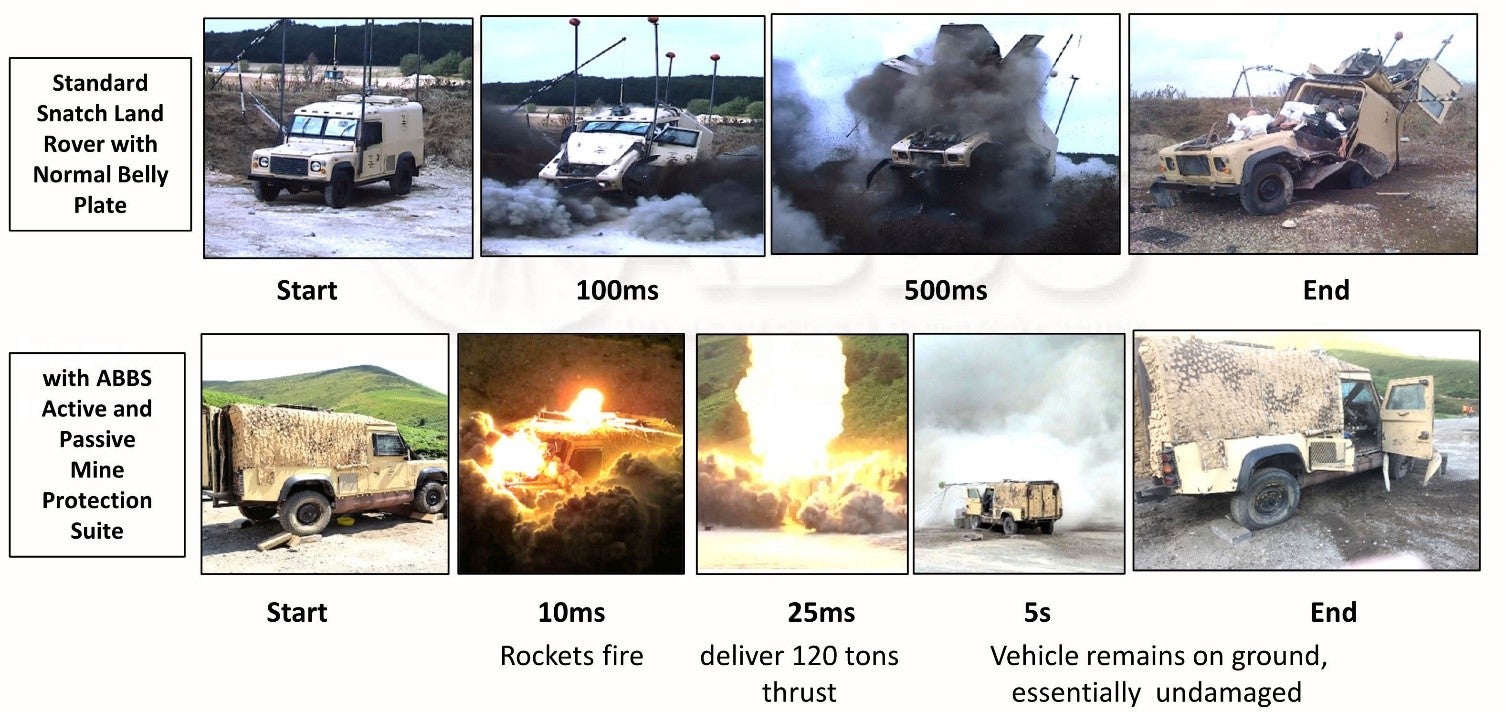

ABBS has developed a suite of active and passive systems designed to offer military personnel complete protection from injury from under-belly mines.

ABBS has developed a suite of active and passive systems designed to offer military personnel complete protection from injury from under-belly mines.

Protective systems for military vehicles

Our systems are:

VGAM™ – Vehicle Global Acceleration Mitigation – Uses Linear Rocket Motors (LRM™) with approximately 9kNs impulse to eliminate G-load injuries.

VAFS™ – Vehicle Active Floor System – Prevents lower limb injuries due to floor shock.

CRBP™ – Composite Reinforced Belly Plate – Minimises deformation and prevents contact with floor and fragment penetration.

Composite reinforced belly plates for military protection

Whilst the active systems, including the novel Linear Rocket Motors, are the key element of the full system in eliminating global acceleration, it is a relatively high cost item both to buy and certify for use on a vehicle due to the fact that it incorporates energetic materials and a sophisticated safe/arm/sensor/control and initiation system.

However, the composite reinforced belly plates, which protect the vehicle from blast damage, are completely passive, and can therefore be certified for service very quickly and at low cost.

For this reason, ABBS is currently focussing on proving the efficiency of the concept by testing at Level 2b (6kg TNT-equivalent under belly) on a civilian Toyota Hilux. This should be completed by the end of 2020, when the system will be available for application to other vehicle designs.

For the Hilux, the current design is well within the weight budget required and the FEA prediction of deformation meets the target set to avoid impact with the floor of the vehicle.

The design concept is applicable to any vehicle, either as the original design or as a relatively simple retrofit.

Technical rationale for the CRBP design concept

The resistance to deformation of the belly plate is a key parameter affecting the whole of the rest of the basic vehicle design.

The higher the deformation, the greater the space that has to be provided between the belly plate and the vehicle floor, otherwise the impact of the belly plate hitting the floor can cause serious injuries to the occupants.

This increased space inevitably increases the overall height of the vehicle, creating a larger target and a higher CoG, leading to less stability and a larger surface area to protect with heavy and expensive armour.

Hence, the increased weight and cost is a direct consequence of the belly plate deformation level. If the belly plate deformation can be reduced, all of these negative factors are improved.

Composite reinforced belly plates to prevent damage to military vehicles

Currently, belly plate designs are frequently based on the V-principle, which does provide much increased stiffness and strength, but it also quite heavy and raises the COG of the vehicle. This reduces stability when travelling over rough or sloping ground, which can result in rollover accidents.

The concept of using a flat belly plate reinforced by composite structures to limit deformation has already been fully demonstrated by ABBS with both 6kg and 12kg tests to AEP55, showing that blast levels in the range of 15kg – 20kg could be defeated by the right designs applied to relatively lightweight vehicles in the 5t – 10t range, albeit that the additional use of the LRM technology would then become essential to control the Global Acceleration problem.