Energy Absorption Experts Team Up to Revolutionize Protection for Ballistic Protective Vests

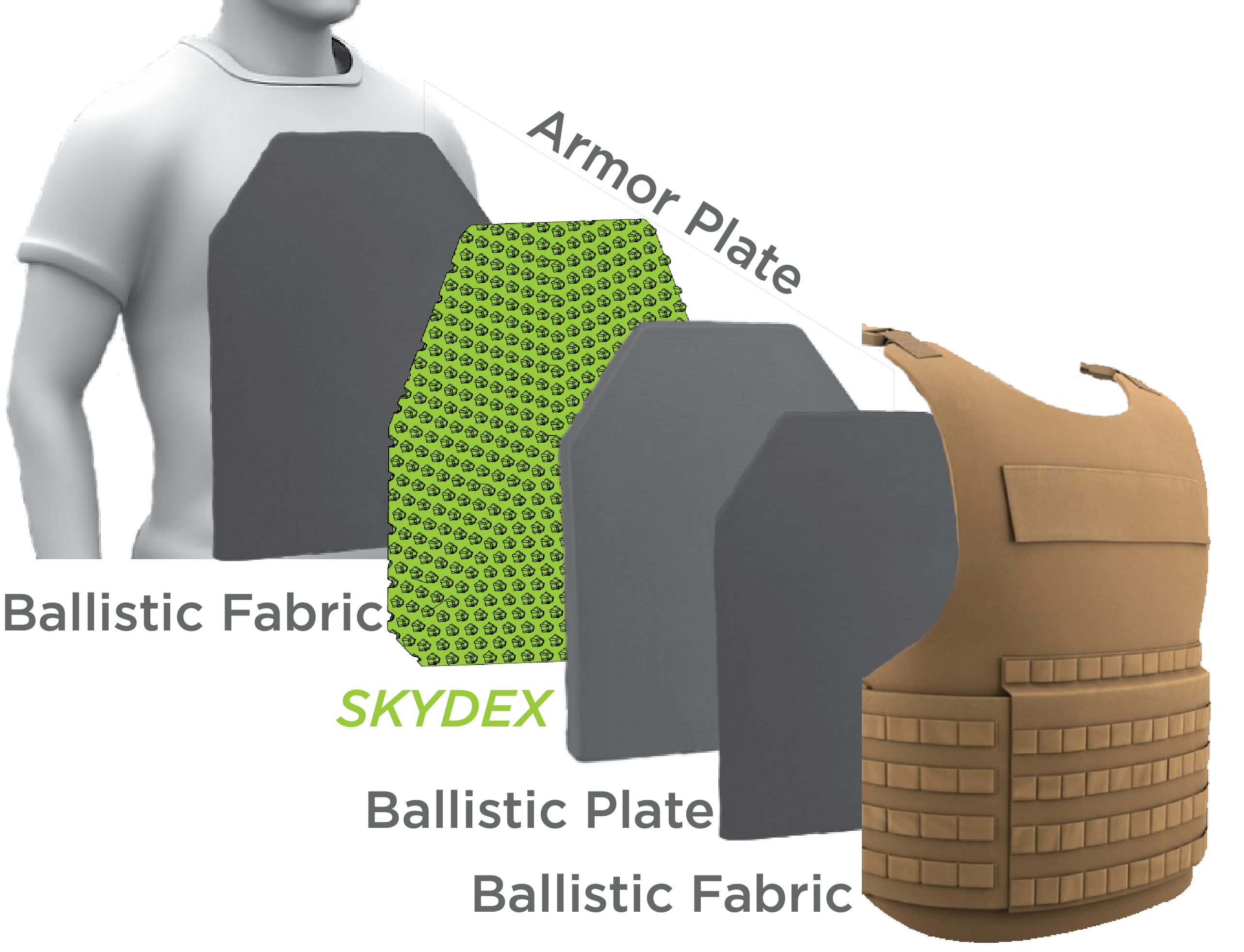

SKYDEX, a global leader in advanced impact mitigation and energy absorption solutions, today announced that the company has partnered with EDAG Engineering GmbH, TSS International BV and Avient Corporation, home to Dyneema®, to develop and prove performance through simulation of an advanced material to protect from behind armor blunt trauma (BABT) threat when wearing a bulletproof vest.

With an existing partnership between EDAG and TSS in the field of shock mitigation for armored vehicles, the two companies began examining how combining energy absorbing technology proven in armored vehicles with ballistic materials used in personnel protection vests can offer the next generation of protection for the ballistic vest market. Focusing on achieving protection from the 7,62 x 39 FeC threat, the main approach for the development was to reduce the BABT to increase the chances of survival. A comprehensive summary of their findings will be showcased at the upcoming Personal Armour Systems Symposium (PASS 2023) held in Dresden, Germany. EDAG and TSS will elaborate on the specific details of their findings regarding the protective benefits achieved by combining the SKYDEX® Ballistic Trauma Reduction Layers (BTRL) and Dyneema® materials.

To initiate their development process, TSS contacted the team at SKYDEX due to their proven track record in supplying blast mitigating materials for armored vehicles. The purpose was to gain insights into the application of their technology in the ballistic plate market.

“We have worked with several industry leaders over the past 5 years to provide advanced materials with our technology that are integrated into ballistic plates to reduce backface deformation,” said Alvaro Vaselli, SKYDEX President and CEO. “TSS has been a great partner in the armored vehicles space and EDAG has provided critical simulations of our technology in vehicles, so we were excited to partner with them on this important development and expand on our mission of protection people and things that matter.”

To provide the ballistic material performance, TSS partnered with Avient, the producers of Dyneema® a leading ballistic material utilized in the personal protection industry. “We are constantly striving to advance our platform and provide materials that perform to the highest industry standards,” commented

Dirk Louwers, Global Marketing Manager for Personal Protection, Dyneema®, Avient. “Dyneema® has been leading the way in ballistic protection for more than 30 years and we are excited to explore innovative ways to use our cutting-edge technology to protect those who protect us.”

With Dyneema® in place to stop the projectile and SKYDEX BTRL effectively absorbing the energy released upon impact, the materials complement each other well in terms of ballistic protection and energy absorption. “The aim of this simulation driven development is to demonstrate how the different materials react when combined to reduce the risk of BABT-related injuries,” said Louis Huijzen, TSS Managing Director. “We found that the Dyneema® and SKYDEX combination produced the most optimal protective composite for soldier personal protection systems.”

Using EDAG’s IMPETUS Afea Solver®, the team was able to develop an effective layering of the selected material combination. “This finite element solver is designed to analyze the stresses and ballistic effects on structures,” commented Jan Hendrik Bohlen, EDAG Project Leader Defence (M.Eng.). “Our unique approach to modelling at the micro and meso level allows us to closely examine the contribution of each component during the impact event and optimize their interactions.”

More information about this revolutionary combination of technologies will be released as part of the upcoming Personal Armour Systems Symposium (PASS 2023) and representatives of each organization will be available to provide additional information.