Oldham Engineering

Fabrication and Machining Solutions for the Defence Industry

Oldham Engineering Ltd is a leading provider of turnkey project management services and high integrity projects for the defence sector.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Oldham Engineering Ltd is a leading provider of turnkey project management services and high integrity projects for the defence sector.

The company provides in-house coded fabrication (BSEN ISO 3834-2), medium-heavy (30t-10m) precision CNC machining and robot welding solutions, as well as complex assembly and testing for bespoke projects and batch production.

Oldham Engineering’s state-of-the-art facility features large fabrication areas, varied machining capacity and a fitting department, enabling the company to provide a complete supply solution to clients.

The company is certified to a wide range of industry standards, including ISO 9001:2015 and ISO 45001.

Design and engineering consultation services for the defence industry

The team at Oldham Engineering Ltd is built on strong engineering knowledge, allowing us to guide our clients through the most complex projects by offering advice on best practice, current standards and product manufacturability.

We offer a complete engineered solution encompassing design, quality management, a pre-manufacturing engineering review, process evaluation, project engineering and commercial NEC3 management.

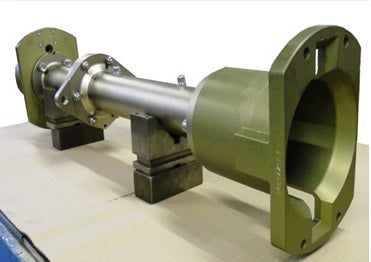

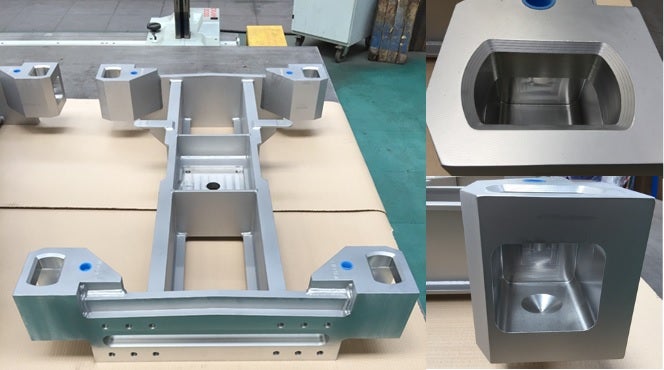

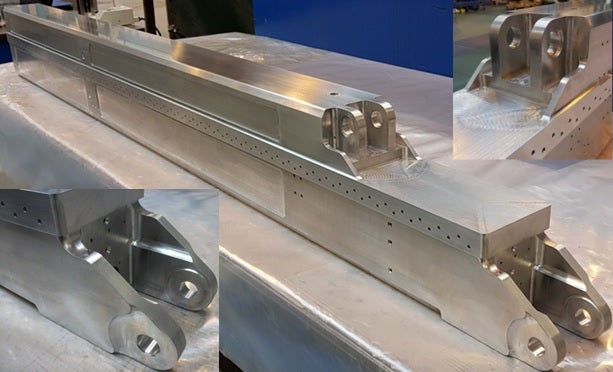

Fabrication and machining for military project requirements

Oldham Engineering is an industry-leader in stainless-steel, carbon steel and exotic alloy fabrications. With 12,000ft² of our 80,000ft² site dedicated to stainless-steel fabrication, Oldham Engineering takes compliance seriously, offering full segregation and ferroxyl testing.

Our in-house resident welding co-ordinator (RWC) is qualified to CSWIP 3.1 and PCN Level 2, enabling us to offer services to support weld test qualification and NDE under ISO 3834-2. We can complete any high integrity batch or bespoke fabrication projects.

In addition, we have a variety of large CNC machinery to provide optimal performance, reliability and accuracy. Our high-end CNC machines and horizontal and vertical borers allow us to deliver high-integrity batch or custom fabrication projects.

Ongoing investment in new machinery and technology is essential to our business, ensuring we remain at the forefront of modern practices.

Fitting, testing and assembly services for defence applications

Oldham Engineering offers a skilled team of engineering fitters who can deal with solutions involving hydraulics, pneumatics and electronics. Complex mechanical projects can be assembled to test interfaces of all components and working mechanisms, plus in-house test requirements for pressure, load, leak, FAT, and others as required.

All of our fabrication, machining and fitting processes are rigorously inspected by qualified personnel using our temperature-controlled inspection room, CMM inspection table, and portable FARO arm.

Our processes are overseen by our dedicated quality department, ensuring compliance throughout the project lifecycle and that the required level of documentation and traceability is accurately recorded.

About Oldham Engineering

At Oldham Engineering, we place a strong emphasis on quality and ensure that our company values are implemented throughout all aspects of the business. We regularly reflect on our practices and past projects, allowing us to lay the foundations for future success.

With committed investment towards structure and resource, alongside specially developed ‘business intelligence’ software for seamless integration with the real-time MRP and shop floor data capture system, Oldham Engineering is equipped for any future market demands.

Contact Details

Website

Email Address

Address

Overens St,

Oldham,

OL4 1LA,

United Kingdom