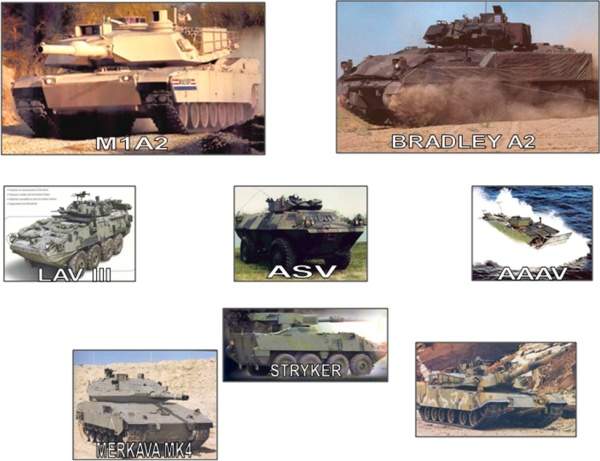

Specializing in optical and mechanical assemblies, Optex has established itself as a critical supplier on multiple armored vehicle platforms (Abrams, Stryker, Bradley), fire control systems (howitzers, .50cal machine guns), and night/thermal vision sights (armored security vehicle, light armored vehicle (LAV), night vision rifle scopes).

Precision sights, periscopes and vision blocks for military use

Optex provides battle-tested collameters, aiming circles, mounts, and panoramic telescopes. Its precision sights, periscopes, and vision blocks are mounted on ships, field artillery systems and combat vehicles. More importantly, they incorporate the latest digital technology to integrate these capabilities and increase situational awareness, while reducing space and weight claims.

Optex Systems is a certified United States Small Business, and has served the international defense industry since 1987. Fully ITAR-compliant, Optex is specifically targeted towards military products and services. Optex designs, builds, and ships thousands of units per month as either a prime contractor to governments or as a sub-contractor to original equipment manufacturers, like General Dynamics Land Systems (GDLS), BAE Systems, and L3 Communications.

Located in Richardson, Texas, US, Optex has access to a talented workforce pool, effective transportation for customers and suppliers, and competitive manufacturing support costs. In addition, Optex has the systems and controls to manage the program (ISO9001:2008, MRP/ERP systems, government-approved accounting systems).

Engineering tests for military sighting systems

Optex has the capability to perform in-house engineering tests on incoming piece parts as well as final assemblies. In some cases, external labs are used when the cost of owning specific capital assets is prohibitive. First article test requirements and associated extreme-use tests are designed to conform to the specified requirement. Production tests performed by quality inspectors include ongoing physical measurements of incoming piece parts, in-process controls, and final outgoing conformance testing.

High-quality armed forces product testing and inspection

Optex has the dedicated personnel to procure material, inspect incoming material, control material, design assembly fixtures/work centers, control the process, test/inspect final product, package and ship the required quantities. These are controlled through documented processes and audited and approved through our ISO9001:2008 quality system.

Engineering capabilities

Optex’s technical staff consists of a variety of individuals who have years of experience in assembling, testing, and inspecting laser protection components and systems. The knowledge base contained within this technical staff comes not only from the engineering function but also other functions, such as quality control, assembly and manufacturing operations, and management positions.

Optex understands the nature of defense manufacturing requirements and associated critical end-user requirements. Internal product management methodology is designed to ensure incoming components meet all of the stand-alone requirements of piece parts, to ensure that processes are developed and implemented so that assembly techniques do not compromise the quality of the finished product, and to ensure that the final assembly requirements are tested properly against the standards called out in all pertinent specifications.