Finnradiator specialises in the design and production of heat exchanger solutions for heavy-duty off-road vehicles, military vehicles, trucks and buses.

Finland is perhaps better known as an exporter of mobile phones and paper machines than as an exporter of automotive heat exchangers. Yet, established back in 1926, Finnradiator has a long history of manufacturing radiators for the automotive industry and focuses on the design and production of radiators for heavy-duty trucks and off-road vehicles used in areas such as military, construction, mining and agriculture.

Copper and aluminium radiators for military vehicles

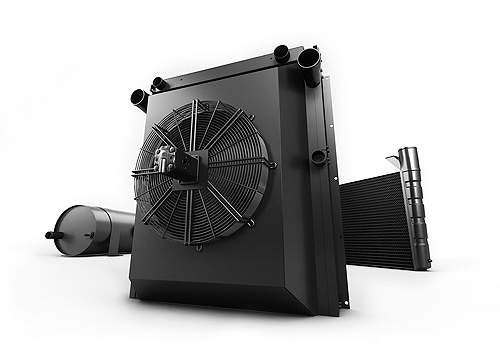

Today’s Finnradiator is an expert in the design and production of copper and aluminium radiators based on either a sandwich or combicooler structure, and supplies water radiators, charge air coolers, oil coolers, combicoolers, complete radiator systems, and expansion tanks. Finnradiator is known as a company that tailor makes products to the specifications of its customers. It provides superior quality in consequence of reduced downtime and failure rate combined with increased availability. It builds its reputation on superior service to its customers in Scandinavia, Central and Eastern-Europe, Australia and Japan.

Worldwide cooperation with other companies in the field and close partnerships with its customers, together with ISO-certified manufacturing, enable Finnradiator to deliver solutions tailored to vehicle manufacturers’ specific needs. While Finnradiator’s speciality is small runs of niche products, the scalability of its operations means that it can offer flexibility in terms of both volume and product type when needed.

With the introduction of legislation in Europe, Japan, and the US designed to reduce emissions from diesel engines in areas such as NOx, CO2, and particulates, coolers will need to be increasingly efficient and durable. This was the motivation for Finnradiator’s investment in CuproBraze technology and the company has had a dedicated CuproBraze production line in operation since 2006.

Corrosion-resistant heat exchangers

External and internal corrosion resistance are better in CuproBraze heat exchangers than in the aluminium type, proven in accelerated corrosion tests such as SWAAT, salt spray and marine conditions. Maintainability and reparability in the field saves critical downtime, which is crucial for reliability, as well as engineering labour. These elements, in combination with the longer and more predictable lifecycle of heat exchangers, are crucial for the integrated logistics support planning of the military vehicle.

Finnradiator’s CuproBraze-based radiators ensure that manufacturers can achieve Euro 4 and Tier 4 emissions standards without compromising on power or having to sacrifice limited space in engine compartments. Units consume less power and charge air coolers, for example, do not need a precooler.

Thanks to their higher tensile strength and greater heat and pressure tolerance, Finnradiator’s CuproBraze products are more reliable, need less maintenance, and offer lower overall lifecycle costs. Cleaning is easy, using pressurised water or air. If a unit does need to be repaired, work can easily be carried out in the field as well, reducing downtime and the need to carry heavy spare part inventories.

Radiators for heavy-duty automotive applications

The enhanced corrosion resistance and overall reliability provided by Finnradiator’s CuproBraze products mean that they are particularly well-suited to use in harsh conditions where radiators can be subject to heavy vibration, such as military applications, mining and construction, timber harvesting, and agriculture.