Touch International (TI) designs and manufacturers innovative edge touch display and touch-enabled devices for high-reliability markets, including the military and aerospace sectors.

Touch International (TI) designs and manufacturers innovative edge touch display and touch-enabled devices for high-reliability markets, including the military and aerospace sectors.

Leading touchscreen technology for defence applications

TI specialises in the production of the latest in projected capacitive (PCAP) multi-touch technology, ranging from 0.5” to 70”.

The company can work with low minimum order quantities (MOQs) and has a library of reference designs paired with industrial-grade displays to achieve optimal development speed and reduced engineering fees.

TI also provides resistive technology for legacy applications and has multiple sizes and configurations of standard designs for reference.

Enhanced touch display technology

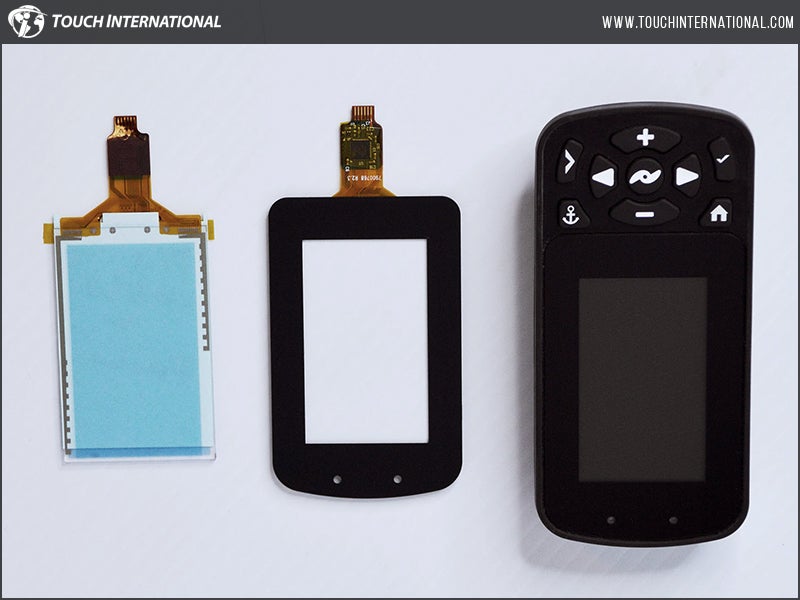

Touch enhancements include EMI, colour, and privacy filters, polarisers, IR filters, custom communication cables, embedded controller options, and custom cover glass.

Cover glass customisation includes thickness, ranging from thin and light to heavy-duty, as well as ruggedised, custom shapes, sizes, curves, and cutouts for buttons.

Cameras and controls, as well as other graphics, such as colours, indicators, logos, and other branding, can also be customised. Surface treatments and coatings include anti-fingerprint, anti-glare, anti-reflective, anti-microbial, and more.

Display enhancements include extended-temperature operation, transparent heaters, high-brightness, sunlight-readability, night-vision (NVIS), and more.

Industrial computing and video processing technology

Various industrial computing options can be integrated as part of a complete package, and the company has reference designs across several form factors to speed up development and reduce costs.

TI can design and integrate multiple applications, including single board computers, compact PCs, OPS media players, and custom Raspberry Pi systems. Operating system options include Windows, Windows Embedded/IoT, Linux, and Android.

Peripheral integration and connectivity complete the computing package, with options including cameras, controls, card readers, NFC/RFID, IoT applications, PoE accessories, repeaters, and a wide range of sensors, such as fingerprint, motion, heat, mechanical, and electrical.

TI also designs and manufactures custom video boards and has reference designs for customer integration, compatible with any resolution (custom/FHD/4K), input/output (HDMI/VGA/RS232/PoE), and more.

Custom housings and complete assemblies for the military

Final assembly design and integration bring everything together, combining the company’s extensive engineering and supply chain resources to deliver complete, plug-and-play touch-enabled solutions.

TI’s industry-leading in-house metal and plastics capabilities include milling, laser sheet cut/bend/weld, large format thermoforming, and hydrographics. Examples of finished products include kiosk housings, stands or mounts, chemical and weather resistant touch PCs, custom hardware adapters, integration, or retrofit.

Custom paint, graphics, and powder coats can be applied to almost any final assembly in order to meet the most demanding specifications or customer requirements.

Touch International’s OFX Series Multi-Touch monitors are complete turnkey touch display packages, suitable for use as-is or with as much customisation required for a specific application, dramatically easing the burden of development from scratch. These monitors are available from 7” to 55” and include medical-compliant and IEC60601-certified configurations.

About Touch International

Headquartered in Austin, Texas, Touch International is certified to IS09001, ISO13485, and AS9100 standards and operates four vertically integrated facilities worldwide.

Successful application examples from previous projects include in-flight entertainment, combat navigation systems, mobile industrial touch PCs, oil and gas pump controls, and DOOH digital signage for multiple military and industrial uses.

Based at a cutting-edge, fully International Traffic in Arms Regulations (ITAR) compliant engineering design centre in Austin, Texas, Touch International can handle any military applications, such as MIL-STD-810F.

Shenzhen and Zhongshan in China operate as commercial off-the-shelf (COTS) engineering, sourcing, and high-volume manufacturing centres, while Bangalore, India functions as a regional sales and engineering hub with complete touch manufacturing capabilities.

All of TI’s in-house engineering and manufacturing capabilities can dramatically reduce customer development time and cost, simplify the supply chain, and yield better products, changing the way companies can approach touch-enabled product design.