The HINTSTEINER Group specialises in the development, engineering and production of high-performance lightweight parts for the defence industry.

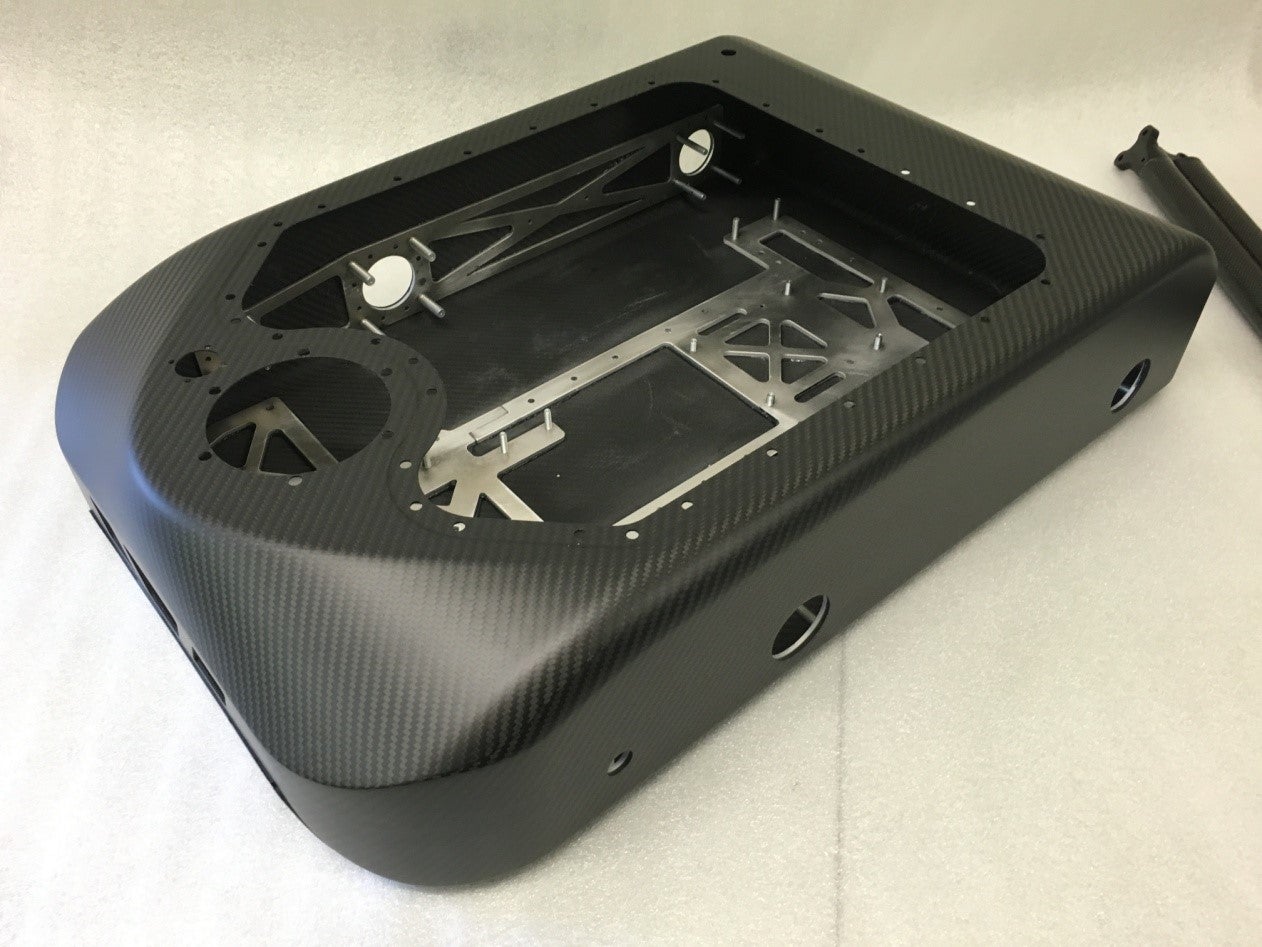

The company utilises advanced composite materials, such as carbon fibre, glass fibre, and aramide, for prototypes and small batches. From structures for launcher and missile systems, over components for military vehicles, to equipment for soldiers, HINTSTEINER has a proven track record of completing projects for various military applications.

Carbon fibre reinforced polymers (CFRP) combine all of the properties that components and mechanical parts need for use under extreme conditions, which include enormous differences in temperature, continuous contact with salt water, and high levels of mechanical stress.

Engineering and production of prototypes and small batches

With decades of experience in the production of components made from innovative fibre composite materials and our wealth of knowledge in the implementation of prototypes and small batches for the defence industry, HINTSTEINER is a reliable choice for a wide range of design and manufacturing solutions.

We manufacture to exceptionally high standards of quality, while always ensuring our services are fully compliant with technical military standards.

We use the following materials and processes in the production of our prototypes and small batches.

Materials include:

• Fibre composites (CFRP, GRP, aramide)

• Polyurethane (rubber, Shore A, rigid foam, flexible foam)

• Metals (aluminium, steel)

Processes include:

– Production of plastic components.

- Foams (hard/soft), injection mouldings, moulding of flexible components, 3D plastic printing

– Production of fibre composite components.

- Autoclave-prepreg technology, resin injection processes, hand lamination

– Production of metal components.

- Metal-cutting (turning / milling), 3D metal printing

Lightweight spare parts for military vehicles

New technological processes and comprehensive technical expertise enable us to supply customers with spare parts in a quick and simple way. Maintenance work on modules, involving replacement of certain components, is not only faster than purchasing a new unit, but also much less expensive.

HINTSTEINER supports clients globally with technical service support for the entire range of systems operated. Customers with only old technical drawings (blueprints) or documentation often struggle to obtain new ones. Using our 3D scanner, we can establish the dimensions of components and manufacture them to a high standard of quality.

The same applies to the definition of materials and material designations that have changed over time. Through new qualification and material research procedures, we have a field book of military materials that enables us to determine a very diverse range of plastics and alloys.

On-site GRP repairs and installation work for the defence industry

Conventional materials have a big problems coping with high salt content, aggressive chemical environments, and extreme climatic conditions. This is why metallic materials soon reach their operational limits when they encounter the ambient conditions at sea or in tropical climates.

Weight reduction is becoming ever more important, as well as CFRP, with much greater use being made of GRP (glass fibre-reinforced plastic). Applications implemented using GRP include supporting structures, observation platforms, water tanks, transmitter masts, containers, and storage vessels.

The light weight of these applications means that they can be constructed and dismantled fairly easily, while the corrosion resistance, acoustic insulation, and thermal and chemical resistance of GRP have advantages over metal solutions.

Optical and functional surface treatment of lightweight parts

Due to the strong position that the HINTSTEINER Group holds in the creation of components for defence technology, we are committed to equivalent levels of surface treatment for military applications, specifically in relation to components for military vehicles.

Reliable surface protection is another key element to maintaining the value and functional capability of military equipment and vehicles. Because vehicles of this kind have long operational service lives, surface protection is very important, which is why we dedicate so much attention to it. The right choice of surface technology and the use of the right surface materials are intended to prevent secondary damage caused by defective surface protection.

In addition to conventional paintwork and powder-coating, HINTSTEINER Group is experienced in thermal spray-coating processes. With our special processes, high functional surface finishes, such as EMC-shieldings, can be provided to our customers.

About HINTSTEINER Group

Located in Styria, Austria, HINTSTINER Group is a leading competence centre for carbon composites and plastics technology in prototype and small series production. We have extensive technical know-how, decades of development experience, a pioneering mentality, and a passion for developing unconventional solutions.

Founded in 1981 with a focus on plastics technology, HINTSTEINER today develops and manufactures on 3,500m² in the carbon composites technology and plastics technology sectors.