Pryme Group offers a complete turnkey service for defence manufacturing, combining precision machining with design capability, fabrication, coatings, hydraulic services, assembly and testing.

Our testing capabilities include PR2 API 6A, endurance product, hydrostatic, gas, packer / plug, high-temperature, cryogenic / low temperature, vacuum, hyperbaric and helium testing.

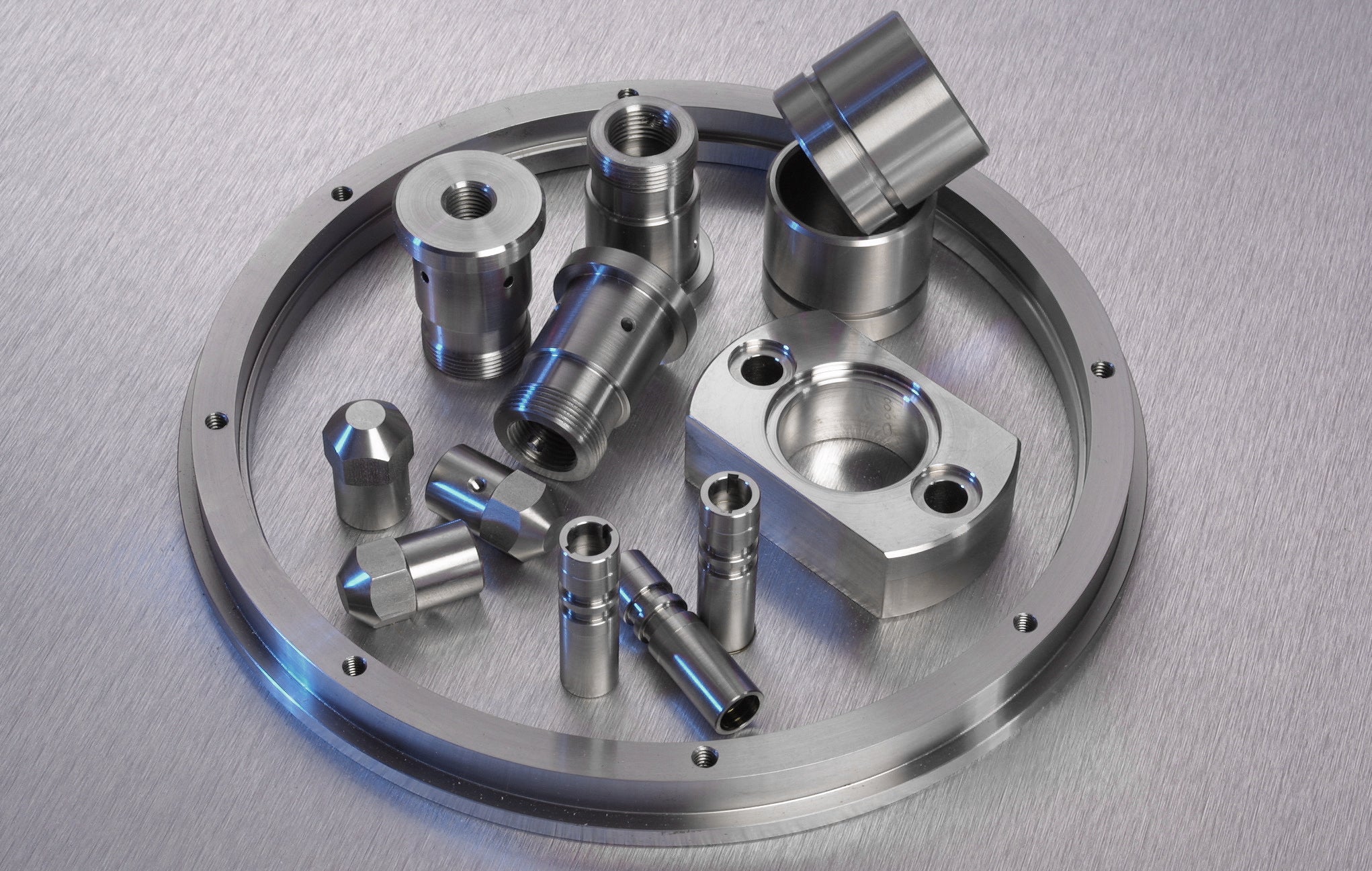

Precision component manufacturing for the defence industry

In order to deliver for a range of manufacturing tasks, including mill turn, horizontal milling, and fourth, fifth and nine-axis capabilities, Pryme Group operates an extensive range of CNC machinery.

The company is capable of accommodating both large and small scale activities with roughly 140 CNC machines in-house, working alongside modern and established technical systems operated by our highly skilled and experienced crew.

Pryme Group offers machined parts from 0.3mm to 2m in diameter and can deliver up to nine axis capabilities. Our company also has one of the largest ranges of STAR sliding head machines in the UK.

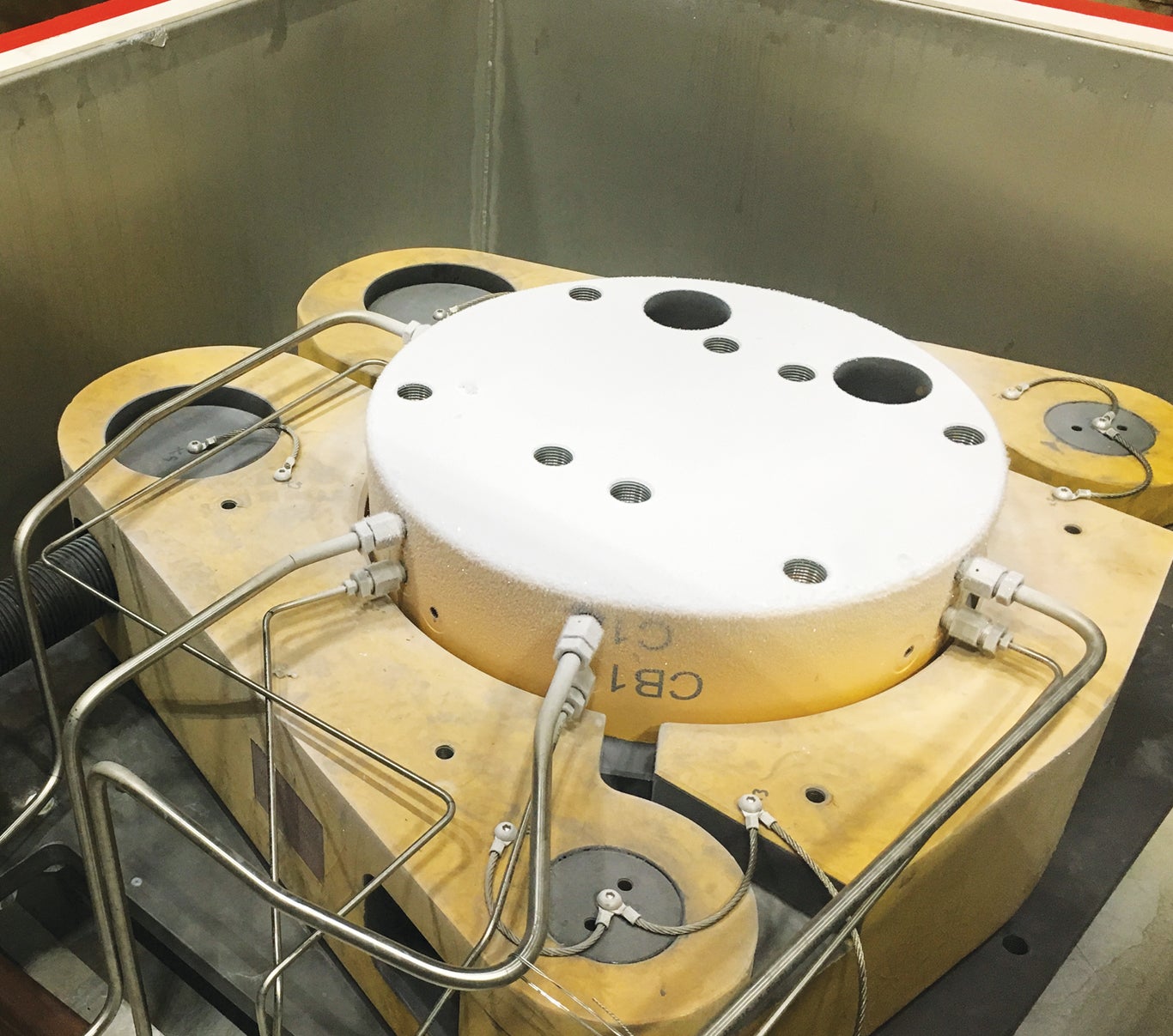

Testing services for military requirements

Pryme Group runs a modern testing facility with 850m internal and 1,000m external capacity. A 20t overhead crane and 5t auxiliary crane, as well as trusted local lifting sub-contractors, offer the ability to handle large test pieces

We offer PR2 API 6A testing of parts through a temperature range of 660°C (1,220°F) to -60°C (-76°F) and gas test pressures of up to 40,000psi (2,757 bar) are possible in state-of-the-art test cells.

Services on offer include PR2 API 6A, endurance testing, hydrostatic, gas, packer / plug, high-temperature, cryogenic / low temperature, vacuum, hyperbaric and helium testing.

Hydraulic systems experts

With a unique blend of technological proficiency and resources, Pryme Group company Hydratron provides products and services to allow the design, manufacture, installation, maintenance and testing of the hydraulic systems.

This includes designing and supplying full hydraulic systems to supplying spare parts and providing lifetime services.

Pryme Group is capable of providing tailored requirements and working within a restricted work floor. Every hydraulic system is tested and assembled at our site under strict quality standards by our exceptionally skilled design team.

Fabrication and assembly services for the defence sector

We have an exceptionally skilled and experienced ISO 9001:2015 and ISO BSEN 3834 approved team of fabricators and welders, which enables us to deliver a completely satisfactory service.

Our welders are qualified to ASME IX, EN287-1, AWSD1.1, NORSOK, ISO 9606-1, ISO 9606-2 and ISO 15614 and are experts in working to a global quality standard ISO 3834.

A comprehensive range of procedures followed for over 50 years allow us to undertake critical tasks and reach out to an extensive range of sub-contract welding work.

Engineering, design and consultancy services

Pryme Group’s skilled engineers are specialists in providing design and consultancy services, from three-dimensional analysis through to prototyping and execution.

With a history of associating with the defence, aerospace and oil and gas industries, Pryme Group offers management services for manufacturing, testing and hydraulics projects.

In order to meet individual client requirements, Pryme Group creates concept products from the 3D design phase to the model prototyping state. In line with our engineering design process, we can manufacture small quantities of finished products for proofing.