CS Hyde Company is a global supplier of high-performance plastic films, silicone rubber products, and coated and non-coated fabrics for the defence industry.

CS Hyde Company is a global supplier of high-performance plastic films, silicone rubber products, and coated and non-coated fabrics for the defence industry.

The company specialises in converting services that it uses to fabricate materials into custom solutions for industry-specific applications.

Materials are only sourced from reputable manufacturers, ensuring quality products and parts designed to specification. All materials are stocked in CS Hyde’s facility, meaning fast and accurate lead times can be provided on all products.

CS Hyde’s inventory is fully traceable and compliant to ASTM and MIL specifications. The company is SAM registered and can be found under NAICS: 326199/322220/326113/561990 and SIC 5131 and 5162.

Converting solutions and materials for military requirements

CS Hyde has been providing materials and converting solutions to the military industry for over 20 years, meeting growing demands for lighter and stronger materials for defence equipment and technology.

The transition from metal components to either plastic or silicone has enabled military technologies to include materials possessing special performance properties such as chemical resistance or high-temperature resistance without additional manufacturing processes. Components designed with plastics or silicone also benefit from design and assembly.

Die-cutting services for army equipment

CS Hyde specialises in simple to intricate die-cutting, providing rotary or digital knife cutting methods in order to optimise cost and efficiency. For components requiring multiple die-cut parts, we can provide kit die cutting services combined with special labelling and packaging for guided installation.

Our lamination capabilities enable us to improve or eliminate mechanical fastening. We supply silicone, acrylic, rubber, and specialty adhesive options for applications requiring low-surface energy for non-common substrates, electrical conductivity for electronics, or adhesive clarity for optics applications.

Performance plastics for defence applications

Polyoxymethylene (Acetal) offers high strength and rigidity over a broad temperature range, as well as low wear, toughness and resistance to repeated impact. Acetal products also benefit from enhanced dimensional stability, long-term creep and fatigue resistance, as well as optimal protection from moisture, chemicals and fuels, including oxygenated fuels and gasohol.

Acetal can be used in multiple components, including gears, slide guides, rotors, handles and bearings. It is also available with a PSA adhesive backing.

Thermoplastics for military aircraft materials and components

Polyetheretherketone (PEEK) has extremely high temperature, chemical, electrical and mechanical resistance. Combing these performance properties with PEEK’s 450°F operating temperature makes this an ideal product for a wide range of military applications.

PEEK is commonly found in military aircraft components, seals, electrical connectors and pump impellers. PEEK film is available in various thicknesses, from .0048in to .060in and can be supplied in rolls, sheets, or die-cut parts, as well as with PSA adhesive backing.

Polycarbonate (PC) films have exceptional impact strength, weatherability and thermoformability. With a higher tensile strength than acrylic and better dimensional stability than Mylar, our polycarbonate film is an effective all-around high-performance material.

Polycarbonate can be used in a range of products, including safety helmets, shields, consoles, panels, and reflectors. The material is available in thicknesses of .010in, .015in, and .020in. We supply gloss / gloss and gloss / matte variants with or without PSA adhesive backing.

Heat and fire-resistant materials

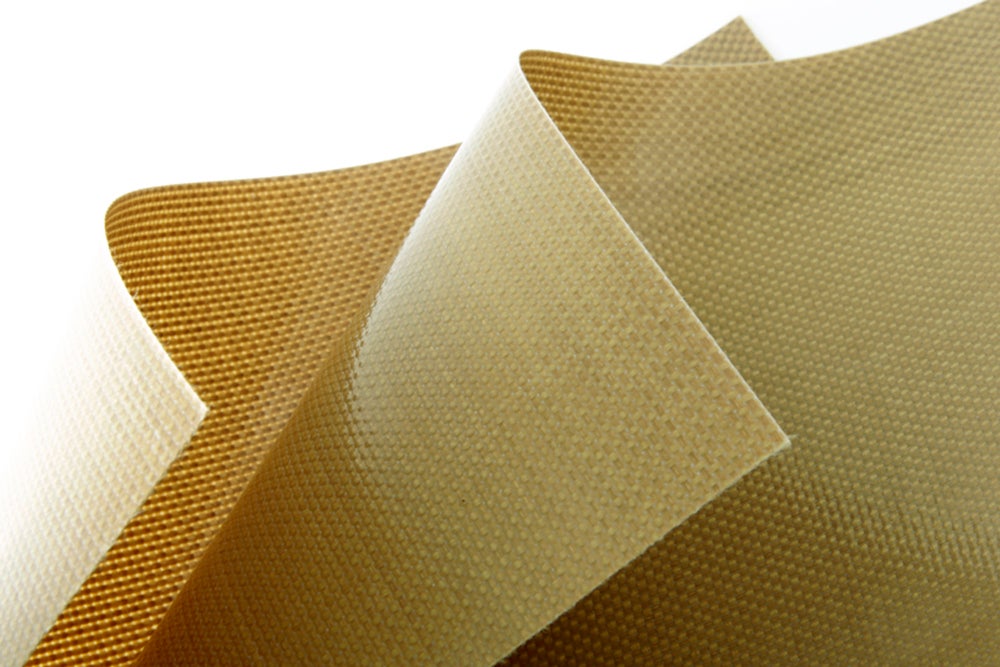

Kevlar® is a highly durable heat and cut resistant material that does not propagate flames and decomposes at 900ºF. Kevlar fabric can be used to manufacture apparel to protect military personnel or equipment from cuts, abrasions, and heat. Heavier-weight fabrics are suitable for gloves, curtains and blankets.

Kevlar Para-Aramid fabric is a combination of aramid and glass fibres that produce a lightweight, high-strength, abrasion-resistant material with a service temperature of up to 650°F. The fabric is flexible with little stretching and can be draped with minimal elongation. It also features high tear strength and optimal dimensional stability, as well as impressive chemical and mildew resistance. Para-aramid applications include ballistics protection, protective gloves, wire and cable, and hose reinforcement.

Kevlar threads are one of the strongest and most fire-retardant threads available on the market. The threads are highly versatile and designed for high-quality stitching and repairs. Both continuous multifilament and spun Kevlar can be used for a variety of sewing operations.

The thread meets MIL-T-87128 are offers resistance to moisture, ageing, abrasion, weather, and high temperatures, enabling its fibres to hold long-lasting stitches even in extreme conditions. Kevlar thread can be utilised in repair gear, backpacks, tent canvas stitching, and boot repair. Continuous multifilament Kevlar can be supplied in both soft and bonded variants, with spun Kevlar also available in dyed colours.