Simpro is the preferred electronics manufacturing services partner with a focus on complex electronics for harsh environments within the defence, offshore, medical and industry sectors. With a particular expertise in radio and ATEX, Simpro can provide support and knowledge throughout the manufacturing process, ranging from development, to prototyping, to mass production with assembly. Our skills and experience has made us one of the strongest national businesses within the Norwegian EMS market.

Customised electro-manufacturing services and accelerated development

As one of the leading electro-manufacturing services (EMS) suppliers in Norway, Simpro can provide a full range of skills and services depending on our clients’ requirements. Together, using our sourcing and logistics departments, we can meet any of our clients’ manufacturing requirements, from single requests to the complete development process of design and development, industrialisation to manufacturing, assembly and testing.

With our ownership in Prevas Development, Simpro provides product design and development in HW, SW and mechanics. Simpro’s unique procedure of simultaneously running the industrialisation and development processes enables us to optimise the product for manufacturing whilst reducing the time it takes to introduce it to the market.

With our extensive skills and practice within the radio electronics (<8GHz), ATEX and subsea industries, we can offer clients a complete customisation package from prototype phase to volume production with electro-mechanics assembly.

ISO-certified electronics manufacturer

Simpro’s quality management is certified according to ISO9001:2008, and we are in the process of being certified according to ISO13485:2012. Simpro is also AQAP 2110 compliant.

All manufacturing work is done according to IPC-A-610, IPC/WHMA-A-620, IPC-7711/7721 Class 2 and 3 for workmanship and J-STD-001Class 2 and 3 for manufacturing processes. All our operators are certified according to J-STD 001 / IPC-A Class 3.

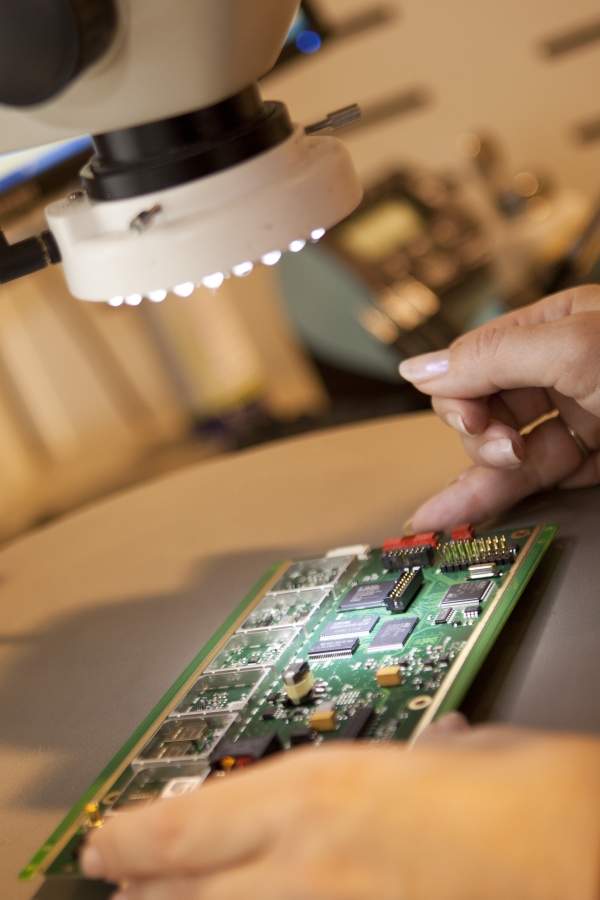

Modern electronics production facilities

Our new and modern production facility located at Løkken Verk, 65km south of Trondheim, Norway, includes two surface-mount technology (SMT) production lines with automated optical inspection (AOI). We use selective and wave soldering machines at our production facilities to increase the production capacity, and our flexible manual assembly lines can easily be adapted to the running production.

Traceability is secured using our PCB laser marker, which is monitored using our new ERP system. The printed circuit board (PCB) and printed circuit board assembly (PCBA) are cleaned in our new water-based washing machine, and our new selective coating and dispensing system automates the process of coating, potting and gluing.

The Simpro Test Department does all test development in-house, with a focus on developing automated tests that are used during the different production steps. In addition to this, Simpro provides environmental stress screening (ESS) and X-ray inspection testing of our products.