Capacitors are made from the same basic components, but the choice of material and their configuration varies widely. They are ubiquitous in virtually all electrical circuits. Some allow only AC current while blocking DC current, while others are used to smooth a power supply output.

They work by storing energy in an electrostatic field that is generated by a potential difference across the conductors. Subjected to a voltage, one plate collects a positive, while the other collects a negative charge. The ratio of the electrical charge and the potential difference (voltage) is called a capacitance (in farads) thus, a capacitor.

Capacitance is at its largest when the surface areas of conductors are vast and very close together. They are usually efficient but occasionally beset with issues related to parasitic induction and resistance in conductors and wiring, while ‘leakage current’ might occur through the insulating layer.

Evolution to supercapacitor

The natural evolution of this device, together with the need for more robust capacitance and heavier charges has led to supercapacitors. As the name suggests, these stores extremely large amounts of electrical charge.

They can be referred to as double-layer capacitors or ultracapacitors because instead of using a conventional insulating layer, they use two mechanisms to store electrical energy: double-layer capacitance (electrostatic origin) and pseudo capacitance (electrochemical).

This combination allows them to have the properties of a capacitor and a standard battery, and can reach capacitances as high as 12000 F (farads). For comparison, the Earth’s capacitance is a miserly 710 µF, 15m times less than a supercapacitor.

These are usually limited to 2.5V – 2.7V. It is possible to go up to 2.8V and above but this shortens their useful service life. They can withstand a much greater temperature range – between -40C to 70C – while electromechanical batteries are limited to 5C to 45C.

Hybrid Capacitors

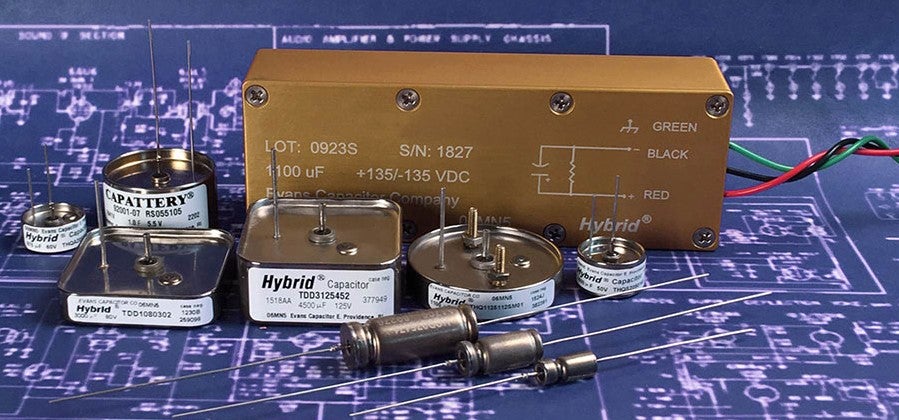

Hybrid capacitors utilise 2 capacitor technologies in one package. Due to their unique construction, they typically offer distinct advantages over traditional capacitor technologies including improvements in power density, energy density, stability over temperature, and improved electrical performance. Examples of hybrid capacitors include hybrid polymer aluminium and hybrid wet tantalum.

Poles apart

Supercapacitors, like electrolyte capacitors, are polar devices that must be connected to the circuit correctly. Research is underway for supercapacitors to replace batteries. An increasingly common usage for supercapacitors is in the drivetrains for electric vehicles, where they almost always outlast their lithium-ion cousins by a huge factor.

With the ability to be charged and discharged a virtually unlimited number of times, supercapacitors only fade by around 20% over a ten-year span because there is little wear and tear in cycling a supercapacitor.

The life of an electrochemical battery is limited, and its performance decline can be measured after hundreds of charge/discharge cycles are over. On average, even the latest lithium-ion batteries do not live beyond their tenth year in use.

A brief history of Quantic™ Electronics and Evans Capacitor Company

Quantic™ Electronics, a portfolio company of Arcline Investment Management, recently acquired Evans Capacitor Company, which has been in the high energy density capacitors business since being founded in 1996.

The newly named Quantic Evans, which makes high-power density capacitors for the defence and aerospace markets, will be an important addition to the stable of Quantic™ Electronics, which has been in the military, aerospace, industrial, and commercial markets for more than a century.

Quantic Evans will continue researching and developing cutting-edge capacitor technology for mission-critical electronics for some of the toughest applications, from deep space to deep underground, and everywhere in between.

Its expertise in high-reliability capacitors manufactured under SWaP (space, weight, and power) principles are critical design considerations for military and industrial sectors. Their range of products includes some of the most power-dense capacitors available.

With a unique hybrid technology that delivers high capacitance, long life, low equivalent series resistance (ESR), high current handling capability, and a custom-design service, it provides capacitors that best meet an application’s needs.