Customers in the electronic connector and cable market are seeking more complex, lightweight and integrated products. Standard parts don’t always meet their requirements, and traditional suppliers may not provide the solutions they need.

By collaborating closely with their customers, connector experts at Omnetics work to understand the challenges they face and support them through sales, engineering and manufacturing. The company recognises the value of feedback, and this allows it to serve its customers with industry-leading standards of customisation and variety, while staying on top of turnaround times.

Omnetics’ Special Projects Manager, Travis Neumann, talks us through how Omnetics works with its customers, and what sets it apart from other suppliers on the market.

The Omnetics approach

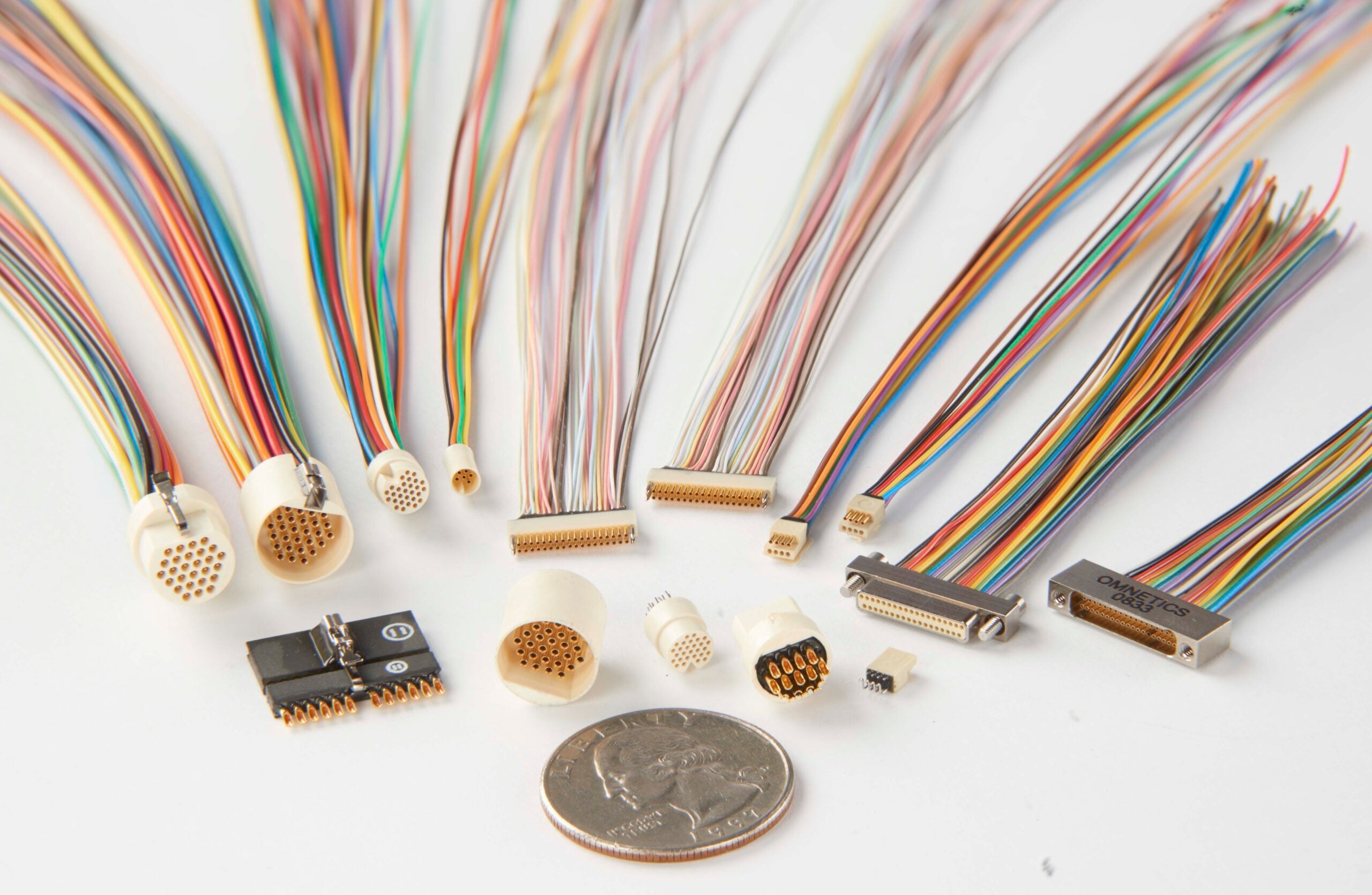

Omnetics has kept up with the market as customer demand evolves. “We sell a lot of individual micro or nano connectors with a pre-set length of wire,” Neumann explains. “Recently we’ve been seeing more harnesses that have multiple different connector companies’ connectors on them, with fairly intricate wiring diagrams and more than 15 connectors of different form factors and sizes.”

As well as increasing complexity, more companies are looking for harnesses, or jumpers, that are small and lightweight. This is one of the main priorities of the increasing cohort of space companies, which also have greater shielding requirements. “We’ve also been seeing an increase over the last year for customer inquiries and design reviews,” Neumann adds.

For most customer requirements, it is not a case of reinventing the wheel. Instead, Omnetics provides solutions which combine off-the-shelf products with targeted customisation. Neumann describes what an Omnetics customer can expect: “We use sales reps to get the ball rolling. Then there’ll be an engineer assigned to the project.”

For customers with less experience, and without a design already in mind, Omnetics sets up effective communication to understand the challenges they face and the requirements they have. “They might be looking for a custom solution if they have challenges that wouldn’t be answered by a standard product,” says Neumann.

Once the Omnetics team has prepared a design, a “feedback loop” is set up. “The customer obviously understands their requirements best,” Neumann explains. “They might see something that they want tweaked, and we do that for them. When the design looks good, we offer to build them a sample, which goes into testing. If that looks good, it will transition to a production order. Otherwise, it goes back into the feedback loop.”

The whole process is highly efficient, says Neumann. Depending on the customer’s requirements, it can take a week or two to get to the design stage. For customers with more experience in the field, the process is slightly different. These organisations might have a clearer idea of what they’re looking for, including wiring diagrams and sealing requirements. They can provide a document package, which is reviewed by Omnetics’ quality, material, engineering and manufacturing experts.

However, in every case, the feedback loop still applies. Omnetics will work with all its customer to develop a solution that’s right for them.

Most importantly, Omnetics’ approach puts the customer’s individual requirements at the forefront. “It comes down to a case-by-case basis,” Neumann explains. “We try to stick with standard solutions because that helps with lead time, but when it calls for custom, we totally do that.”

A world-class offering

It is this approach that enables Omnetics’ solutions to address its customers’ challenges so effectively and has positioned the company as an industry leader. “There’s a number of things Omnetics does really well,” says Neumann.

With over 30 years of experience, the company provides its customers with a world-class offering. The combination of sales, engineering and manufacturing expertise, and decades of experience, means that Omnetics can offer customers solutions they may not have previously considered to address their challenges in the best possible way.

In addition, Omnetics isn’t afraid to offer connectors to customers from multiple suppliers, as well as their own, to provide the most effective solution. “We’ll gladly put those connectors together into a harness,” says Neumann. “Not all companies do that type of work.”

Guided by an ambition to solve its customers’ challenges as efficiently and effectively as possible, Omnetics continues to set itself apart as a market leader.