Electronic devices across the application spectrum are becoming smaller, and connectors and cables are following suit.

Microelectronics began with the invention of the integrated circuit, when small, and then later larger integrated board circuits were formed onto a single silicon chip. And this reduction in size and increase in performance led to commensurate miniaturisation in the sizes of connectors and cables as well.

Ranging from rugged units used within components for space vehicles, human wearable, implantable and insertable devices, remote surgery equipment, smaller and smaller communication platforms – and a huge range of other types of electronics – the sheer breadth of designs, materials, environments and technical abilities that the humble connector has to apply to are mind-boggling.

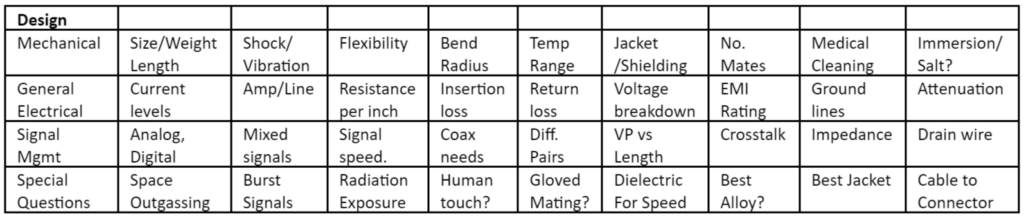

So, the first protocol for anyone needing a connector/cable is for its application design engineers to note as many variables as possible in terms of performance required from the connector in question.

The table below gives a broad range of the questions that must be answered prior to approaching a connector manufacturing company.

Beginning the custom journey

To start with, the environment and application in which the connector will be subjected to have to be fully understood by asking the following questions:

- What type of mechanical, electrical, signal management or a combination connector/cable is needed?

- What type of environment will it be used in?

- Harsh – meaning extreme temperatures, excessive vibration, changes in inertia/acceleration

- Medical device – human wearable, implantable, insertable or remote surgery equipment

- What materials fit the profile of the application?

Once these, and other questions based on end-usage have been answered, the fabrication can begin.

Cable/connector markets and industries

Space vehicles

Apart from the big-ticket space programs reaching the Moon and Mars as well as upcoming deep space projects such as the Jupiter Icy Moons Explorer (JUICE, scheduled for launch in 2022, an initiative between the European Space Agency and its main contractor, Airbus Defence and Space), there is a plethora of small scale low-to-medium and high Earth orbit vehicles blasting into deep space for all sorts of applications.

These include satellites for:

- High-resolution imagery

- Global positioning system (GPS)

- Communications

- Remote sensing

- Navigation

- Nano satellites, CubeSats and SmallSats

And as more applications are designed, we will continue to see different types of space vehicle technology emerging as a result of innovation within the industry.

Devices for use by humans and animals

Human wearable includes smartwatches, body-mounted sensors, fitness trackers, augmented reality (AR) headsets, hearing aids and many more.

Human implantable include pacemakers, implantable cardioverter defibrillators (ICD), insulin pumps, glucose monitors and pressure sensors in vascular systems.

Human insertables include prostheses, cochlear implants, drug delivery pumps and devices for spinal cord and deep brain stimulation.

Remote surgery

Also known as telesurgery, the use of this type of surgical tool is becoming more widely accepted as it has demonstrated its benefits in allowing for procedures to be performed across widely distributed geographical locations. Concerns raised are usually around patient privacy and the stability of the digital connection between surgeon and device.

Communication platforms

The variety of these covers a huge range, from mobile phones to phone masts, from radio to signal repeater stations, from ground control to earth-orbiting digital imaging, weather, GPS, and other satellites.

Other electronics devices

From the humble 2-pin power cable connecting a device to electricity to multi-form connectors that can bridge power (electricity), fibre (for digital binary signals) and data (information transfer), a connector can be very complex, limited only by the application’s requirements and the design engineer’s ingenuity.

And the above information tells a fraction of the story of cable/connectors’ range of designs and applications.

Non-standard cable and connectors

Solutions to non-standard cable and connector combinations are reasonably easy to source. There are many companies that have services that can be engaged to create a customized connector design for a new application.

Omnetics Connector Corporation has been doing this for more than 35 years. They have a refined process that is simple to engage, based on engineer-to-engineer communications. Turnaround times for both support and fabrication are short with an emphasis on design transparency. Omnetics’ experience and history within inter-connect design help them seamlessly devise a solution and long-term partnership with prospective clients that will be perfect for the job, all the while designing within your inter-connect budget.

Omnetics Connector Corporation has solid modelling designers with experience in speciality connectors and cables. Engaging with them to define size and shape, an application-specific prototype can be fabricated rapidly by automated machining equipment and 3-D printing to create the first article products. A solid model can be ready within two to three days for the client’s team to review. New applications using the latest chip designs demand very low power and transmit very low voltage, higher speed digital signals within systems. Circuit density increases result in very small cables and low-profile connectors being required.