Protection Ensemble Test Mannequin (PETMAN) is a humanoid robot developed for the US Army to test the special clothing used by soldiers for protection against chemical warfare agents.

The anthropomorphic robot has increased capabilities over the earlier mechanically operated suit testers, which allowed only a limited number of motion movements while conducting tests.

PETMAN robot development

Funded by the US Department of Defence’s Chemical and Biological Defence (CBD) programme, the PETMAN robot was developed by Boston Dynamics, together with the partners MRIGlobal, Measurement Technology Northwest, Smith Carter, SRD, CUH2A, and HHI.

Contracts to develop the integrated mannequin system and testing facilities were awarded in November 2008. The PETMAN was unveiled in October 2009. Footage of the robot featuring its capabilities was released in October 2011. Most of the details of PETMAN, however, have been kept confidential.

MRIGlobal concluded a five-year programme called Individual Protective Ensemble Mannequin System (IPEMS) in December 2013 for the production of a mannequin robot and high-containment chamber to test protective clothing for the U.S. Department of Defense. PETMAN was a part of the programme.

PETMAN is used to test and evaluate the next generation hazmat suits and other individual protection ensembles used by troops, in controlled environmental conditions.

Contractors with a role in the CBDP

In April 2009, the Defense Advanced Research Projects Agency (DARPA) awarded a $26.3m contract to the Midwest Research Institute (MRI) towards the development of IPE and the PETMAN.

MRI, being the lead contractor, is responsible for systems engineering, chemical expertise, programme management and the entire systems integration.

Measurement Technology Northwest was sub-contracted to develop the special mannequin physiology and thermal control systems. Containment chamber for the robot was designed by Smith Carter CUH2A. The exposure chamber (testing facility) was built and installed by HHI Corporation.

Other partners include Oak Ridge National Lab. Design and fabrication of the PETMAN has been completed by Boston Dynamics. The human simulation software, tools and systems provider had earlier developed the quadruped BigDog robot in 2005. Other products of Boston Dynamics include LittleDog, RiSE, Legged Squad Support System and Cheetah.

PETMAN humanoid robot design

The PETMAN is similar to a Hybrid III standard crash test dummy. The system integrates a control room, ingress / egress support, exposure chamber and an integrated IPE mannequin. The robot can test the suits in a chemically exposed chamber and control room. The exposure chamber supports the functionality of the robot through data acquisition, agent dissemination and environmental control.

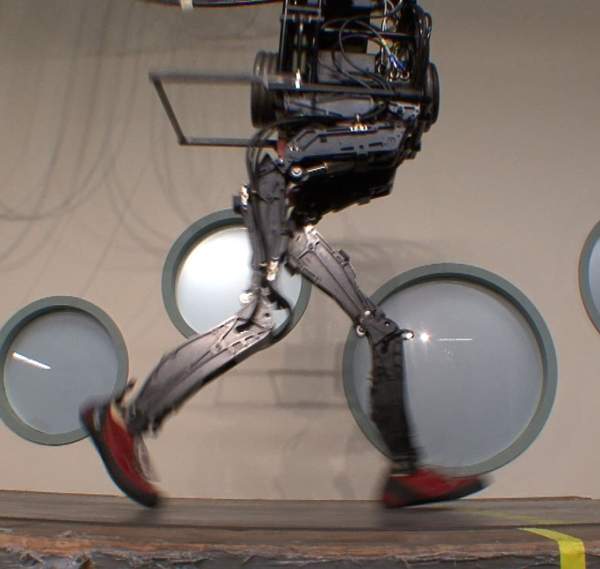

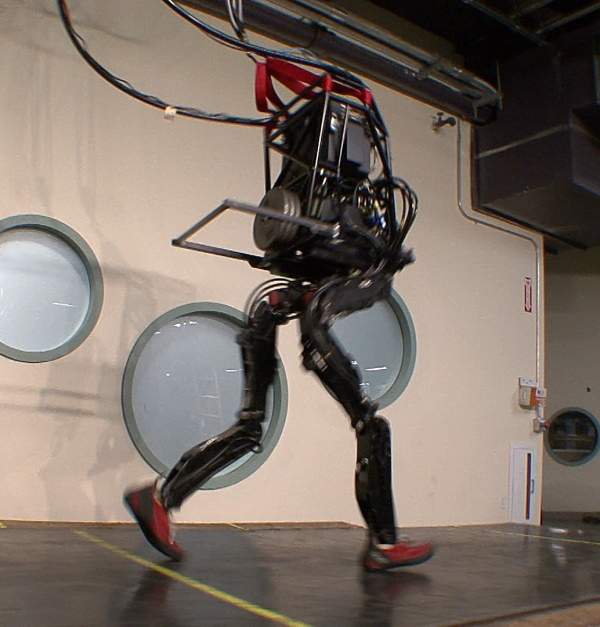

The bipedal robot weighs about 80kg (180lb) and is nearly 6ft (1.75m) tall. PETMAN demonstrated a top walking speed of about 4.4mph (7.08km/h), making it the fastest bipedal robot in the world (Honda’s Asimo robot has a top walking speed of 7km/h).

The robot uses hydraulic actuation and articulated legs with shock absorbers for operations. The unveiled prototype has an onboard computer, several sensors and other internal monitoring systems. Its functions are currently operated through controls on tether. Human actions were deployed on the robot using studies conducted on motion-capture systems.

Protection Ensemble Test Mannequin features and capabilities

The PETMAN is designed to have human-like capabilities. It is based on the similar mechanical design and walking algorithm used for the four-legged robot, BigDog, which can carry heavy payloads in rough terrains.

The PETMAN can self-balance on its two feet and move freely, walk, crawl and perform suit-stressing calisthenics as well as squat thrusts to test chemical exposure. It can also balance when shoved.

The robot provides realistic test conditions by exhibiting human physiological characteristics during physical exertion such as temperature control, sweating and humidity, inside the protective clothing.

The PETMAN can be used to perform various other tasks dynamically in emergency situations, such as search and rescue operations in fire, nuclear and other hazardous conditions, without human exposure.