The AEV3 Kodiak, launched by Geniepanzer in Switzerland, is an armoured engineering and mine clearance tank that can meet the technical and tactical needs of modern day armed forces.

Germany-based Rheinmetall, the co-producer of the Leopard tanks, had teamed up with RUAG of Switzerland to develop, manufacture and market the Kodiak tanks.

AEV3 Kodiak is based on a modified Leopard 2 main battle tank (MBT) chassis and provides heavy duty engineering required in a combat environment.

The AEV3 Kodiak vehicle was showcased at the IDEX 2017 international defence exhibition and conference held in February 2017.

Development of the AEV3 Kodiak

The Kodiak development project started taking shape in 1999, when the Swedish Defence Materiel Administration, FMV, was asked to secure an armoured engineer vehicle. The Netherlands, Denmark, Spain and Switzerland were seen as the potential partners for the collaboration.

Collaboration between Switzerland and Sweden reached a phase where an offer could be made for production. Negotiations between the two countries, however, broke down in December 2001 because of the latter’s inability to pay the required additional funding.

A fresh collaboration was started between Switzerland and Denmark in 2002 and a prototype was developed by Switzerland and Rheinmetall Landsysteme in 2003. Denmark pulled out of the project before the final negotiations.

The Netherlands later expressed interest and the go-ahead was given by the government in December 2007. The two countries concluded a contract with Rheinmetall Landsysteme in January 2008.

Construction of the mine clearance tank

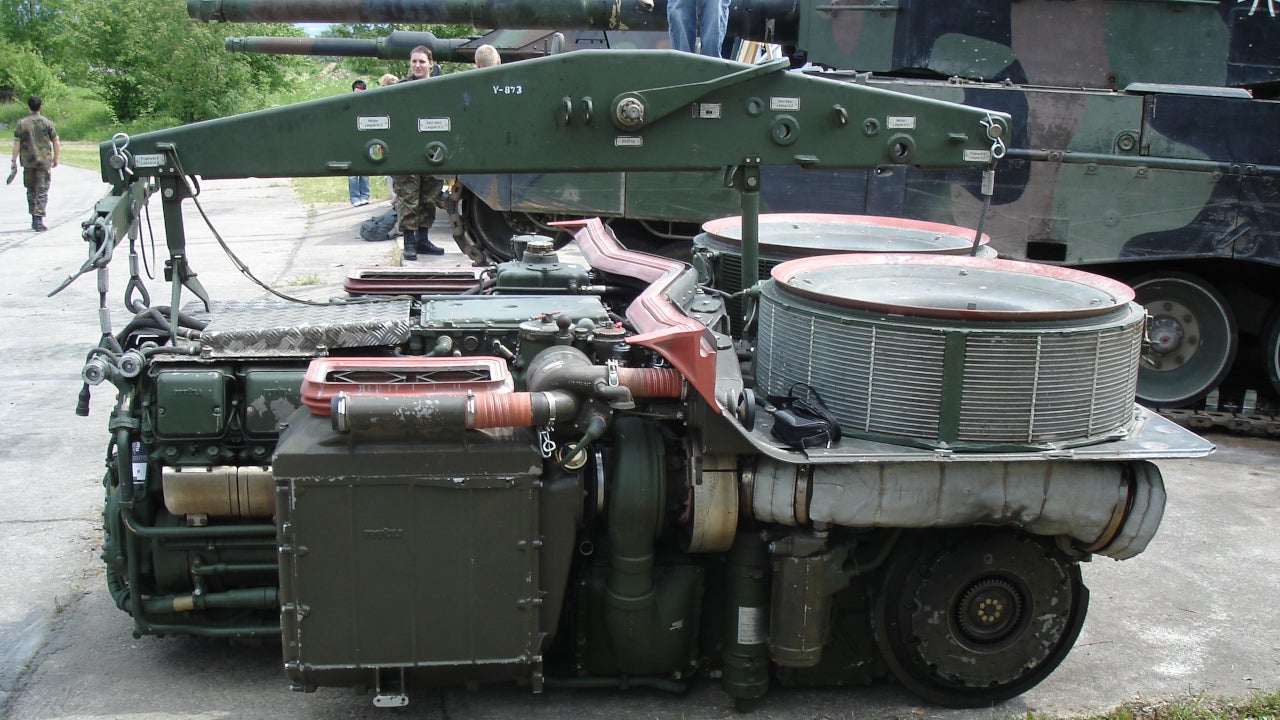

Kodiak was initially considered to be based on the Leopard 1 MBT but, after in-depth study, the Leopard 2 was found to be more suitable to be converted into an AEV. The surplus Leopard 2 MBTs supplied by the Swiss Army are rebuilt and given the shape of multifunction armoured engineer vehicle.

The Leopard 2 MBT chassis is stripped in the workshops in Skovde, Sweden. The stripped vehicle is then sent to the RUAG facility in Switzerland, where the front portion is removed to obtain crew modules and fixtures for the hinged excavator arm and other equipment.

High temperature climatic testing of the vehicle was undertaken in Zaragossa, Spain, and low temperature testing was carried out in Boden, Spain.

Armoured engineer vehicle design and features

AEV3 Kodiak has a length of 10.2m, transport width of 3.54m and a height of 2.3m. The combat weight of the vehicle is in MLC 70 military weight category.

The vehicle is equipped with a hinged arm excavator with a quick-change tool system for fixing other tools, such as a universal gripper, a hydraulic hammer and a concrete crusher. There is also an expandable bulldozer blade that can be substituted with a mine-clearing device when required. Bulldozing capacity of the vehicle is 350m3/h.

The mine breaching system includes Pearson Engineer Mine Plough (EMP), Lane Marking System (LMS) and Demeter magnetic signature device. Ploughing can be done up to a depth of 30cm. Winch system features two 9t Rotzler capstan winches, each provided with a 200m long cable.

Armament and self-protection

The vehicle is armed with a remote-control weapon station that can be outfitted with a 12.7mm machine gun or 40mm automatic grenade launcher (AGL). The weapon station can be mounted with an IR camera, daylight camera and laser range-finder. A smoke grenade launcher is also fitted.

The AEV3 Kodiak is equipped with a nuclear, biological, chemical (NBC) suite for protection against direct contact with and contamination by radioactive, biological or chemical substances.

It is also equipped with an integrated mine protection system and the crew compartment features a heating and cooling system. It can be incorporated with a battlefield management system or a radio and intercom system as required by the customers.

Bomblet protection was provided for the Dutch version.

Mine and obstacle clearance capabilities

Enhanced effectiveness and functionality of the tank enable the combat engineers to build and demolish obstacles in combat, including minefield breaching.

The tank boasts the characteristics of an MBT and an engineering vehicle. It is provided with high level of protection against ballistic and landmine threats. It can be used for civil purposes, such as disaster relief missions and peace enforcement apart from military missions.

The MBT was developed in 2002 to meet the operational requirements of the Swiss Army. The countries using Leopard 2 are expected to be the potential buyers of the Kodiak.

Several countries have already expressed interest in buying the MBT. Contracts for 42 vehicles had been signed by the end of 2010.

Orders and deliveries of the AEV3 Kodiak

The Swiss Army ordered 12 Kodiak tanks worth CHF95m ($117m) in 2007 and took delivery of The first five units from RUAG in December 2011.

The Netherlands Ministry of Defence and the Swedish FMV jointly placed an order worth €100m ($155m) for the procurement of Kodiak vehicles in January 2008. The Netherlands Army purchased ten vehicles and the Swedish Army purchased six. Rheinmetall delivered the first Kodiak AEV 3 S to the Swedish Army in November 2011.

Akers Krutbruk was contracted by Rheinmetall in January 2009 to supply a protection solution for the Kodiak tanks.

Singapore purchased fourteen AEV3 Kodiak vehicles which were ordered and delivered in 2014-2015. The vehicles are known as L2-AEV in Singapore and are operated by the 38th Battalion, Singapore Combat Engineers (38 SCE).

Engine and mobility

The AEV3 Kodiak is powered by 1,500hp MTU turbocharged diesel engine. The engine is identical to that used in the Leopard 2 tanks.

The vehicle moves at a maximum speed of 68km/h and it can negotiate a gradient and side slope of 60% and 30% respectively. The front ramp angle of the vehicle is 26°.

Kodiak offers 0.92m climbing capability, ditch crossing ability of 3m and fording capability of 2.25m.