The South Korean K1A1 main battle tank.

Rotem (part of the Hyundai group) has developed the K1 series of vehicles, which includes the K1A1 120mm main battle tank, the K1105 mm main battle tank, K1 ARV armoured recovery vehicle, and the K1 AVLB armoured vehicle launch bridge. The vehicles are built at Rotem’s automated production facility at ChangWon.

The first two prototypes of the K1A1 successfully completed operational tests in 1997 and the tank is in production and in service with Republic of Korea Army. Total requirement is for about 300 K1A1 tanks, scheduled to be in service by 2010.

Rotem is developing the successor to the K1A1, the K2 Panther, which is armed with a 120mm/L/55 smoothbore gun with automatic loader and has uprated engine and improved armour. Three pre-production tanks have been completed. It is planned that about 680 K2 tanks will be produced from 2011.

K1A1 main battle tank

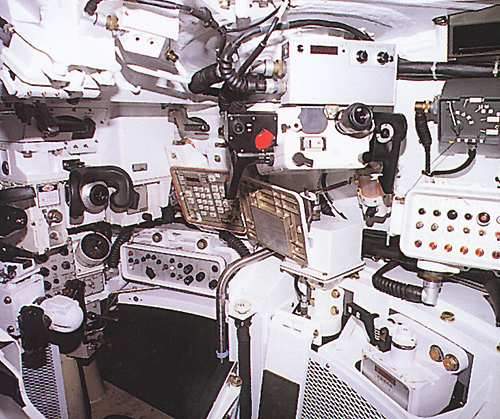

The K1A1 is an upgraded version of the K1 MBT. Its firing range is enhanced by a 120mm M256 smoothbore gun, together with an improved gun and turret drive system. The M256 gun is also installed on the US M1A1/2 main battle tanks. A new ballistic computer for 120mm munitions has higher processing capacity and speed.

Samsung Electronics, now Samsung Thales, are providing the fire control system including the Korean Commander’s Panoramic Sight (KCPS) which includes a thermal imager with 288×4 focal plane array, KGPS gunner’s sight with thermal imager, eyesafe laser rangefinder and dual field of view day TV camera and KBCS ballistic fire control computer.

The race ring turret bearing provides improved sealing for fording and turret slewing characteristics. The fire suppression system has been equipped with a thermal wire fire sensor in the engine bay.

K1 Republic of Korea Indigenous Tank (ROKIT)

The K1 has been operational in the RoK Army since 1986 and is known as the Republic of Korea Indigenous Tank or ROKIT. Following early design work based on US M1 technology, the K1 tank was designed and produced by Korea. The manoeuvrability of the tank is optimised for the varied geographical features of Korea, which include mountainous terrain, jungle, paddy fields and swamp.

The main gun is a 105mm rifled high-velocity cannon with a coaxial 7.62mm machine gun. The commander’s station is equipped with a 50-calibre machine gun and the loader’s station with a 7.62mm machine gun. The turret slews at 750mm a second and elevates and depresses at 400mm a second.

The commander’s panoramic sight has three modes of operation: align with the main armament, independent tracking and gunner override. The commander has the option of handing off the target to the gunner or of slaving the gun to the commander’s sight and initiating the fire. The K1 has demonstrated a first round hit probability of greater than 90% when firing on the move at a moving target.

The Raytheon Gunner’s Primary Sight Subsystem (GPSS) is stabilised in two axes and includes a thermal imager and laser rangefinder. The gunner’s ballistic computer automatically downloads crosswind data, vehicle cant, azimuth tracking rate and range. The gunner manually inputs data for air pressure, air temperature, barrel wear, barrel droop and ammunition type.

PROPULSION

The Kl is equipped with a turbo-charged 1,200hp MTU MB 871 diesel engine providing a power to weight ratio of 23.5hp/t. The transmission has a planetary gear train and a hydrodynamic torque converter. In high gear, the Kl can attain a maximum road speed of approximately 65km/h. The low ground pressure of 0.87kg/cm² enables it to successfully manoeuvre in sodden or sandy terrain.

The Kl has hydro-pneumatic suspension and torsion bar springs. The suspension system also provides vehicle attitude control or ‘kneeling’ capability, which increases the main gun depression angle to a maximum of minus 10°.

K1A1 family of vehciles

The Kl armoured recovery vehicle has a crane system with the ability to lift up to 25t, while the main winch system is capable of towing a maximum of 70t with a guide pulley.

The Kl armoured vehicle launched bridge can launch and retrieve its 22m-long bridge to span gaps up to 20.5m, allowing a 60t (MLC 66) vehicle to cross. It takes only three to five minutes for launching and ten minutes for retrieving the bridge.

The mine-clearing roller system can be installed to detect and detonate land mines. It is capable of clearing pressure mines at a rate of 16km/h.