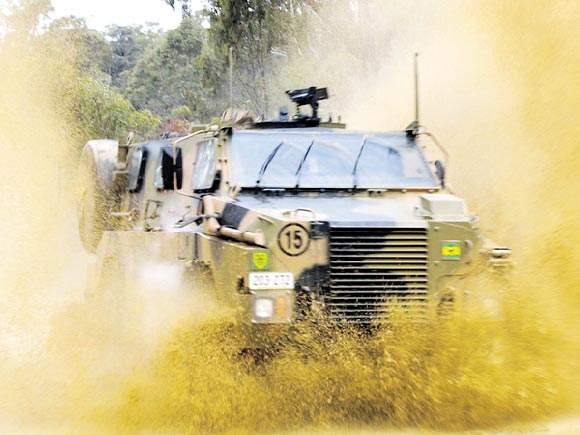

The Bushmaster infantry mobility vehicle

The Bushmaster 4×4 armoured vehicle has been deployed in Afghanistan with the Australian Army. The Bushmaster armoured vehicle, developed by Thales Australia (formerly ADI) in Australia is in full production at Thales’s protected mobility systems manufacturing facility at Bendigo, Victoria.

The Australian Army has tested the vehicle over thousands of kilometres in the extreme climatic conditions and terrain from sub-zero mountain areas to desert and tropical conditions in north Australia. In July 2002, the Australian Army awarded a contract to ADI for 300 Bushmaster infantry mobility vehicles in six variants: troop transport, ambulance, direct fire, mortar, engineer and command.

With a road cruise speed of 100km/h, the Bushmaster transports troops, quickly and comfortably and is suitable for deployment in complex, diffuse and lethal operational environments such as Iraq. The Bushmaster family of vehicles provides high-level protection against anti-tank mines, improvised explosive devices, mortar fragments and small arms fire.

Bushmaster orders and deliveries

The first of 300 Bushmaster vehicles was delivered to the Australian Army in August 2004 and the vehicle was operationally deployed to Iraq in April 2005 and Afghanistan in September 2005. Deliveries completed in 2008.

The 500th Bushmaster vehicle was completed in October 2008. In June 2006, the first batch of 152 troop transport variants completed delivery.

In February 2006, ADI signed a licensing agreement with US-based Oshkosh Truck Corporation to market, manufacture and support the Bushmaster for North American customers and countries eligible for foreign military sales. In January 2007, Oshkosh was awarded a contract by the US Marine Corps for two category II mine-resistant ambush-protected (MRAP) vehicles based on the Bushmaster. The Bushmaster variant was withdrawn from the MRAP competition in August 2007.

In August 2006, the Royal Netherlands Army placed a contract for 25 Bushmaster vehicles, for operations in Afghanistan. For speed of deployment, the vehicles were supplied from those being built for the Australian Army. In August 2009, Netherlands placed an order for 14 Bushmasters, bringing total vehicle orders to 86.

In December 2006, the Australian Army ordered a further 143 vehicles. In August 2007, the procurement of another 250 vehicles was announced by the Australian Army and a further 293 vehicles were ordered in October 2008. Total procurement for Australia is 737 vehicles. The Australian Defence Force placed an order for 101 Bushmasters in May 2011. A further order for 214 vehicles was announced in July 2012.

In May 2008, under an urgent operational requirement, the UK placed an order for 24 Bushmaster vehicles for deployment to Iraq and Afghanistan.

The 1,000th Bushmaster vehicle was delivered to the Australian Defence Force in June 2013.

In December 2013, the Jamaica Defence Force placed an order for 12 Bushmaster vehicles and a five-year support package. The vehicles were commissioned into service in January 2016.

The Japanese Ministry of Defence placed an order for four Bushmaster vehicles for its Japan Ground Self-Defence Force (JGSDF) in April 2014. The deliveries were completed in March 2015.

In June 2015, Netherlands ordered for 12 new Bushmaster vehicles. The deliveries are scheduled to conclude by mid-2016.

Bushmaster remote weapons station

Some of the vehicles are fitted with a remote-controlled weapon system, and all vehicles have the Thales SOTAS M2 multimedia communication system. The vehicles were deployed to Afghanistan in October 2006. In November 2007, the Netherlands Army ordered an additional five vehicles to replace vehicles damaged in Afghanistan. 13 were ordered in June 2008, 18 in August 2008, nine in January 2009 and 14 in June 2009.

In September 2006, it was announced that Australian Army Bushmaster vehicles would be fitted with a remote weapon station (RWS), for added troop protection. A total of 44 Raven R-400 weapon stations from US-based Recon Optical, and electro-optic systems (EOS) from Australia, have been ordered and upgraded vehicles are to enter service in 2008.

Tactical armoured patrol vehicle (TAPV) programme

In June 2010, Thales Canada signed a teaming agreement with DEW Engineering and Development to offer its Bushmaster for Canada’s tactical armoured patrol vehicle (TAPV) programme. Thales has been shortlisted in the pre-qualified bidders list, but the final contract was awarded to Textron Systems Canada.

In February 2010, the Bushmaster single-cab utility variant was selected by the Australian Department of Defence for its LAND 121 phase three programme.

Bushmaster crew cabin

Bushmaster is designed to transport up to ten troops. The cabin, with a 1,415mm headroom, is fitted with eight face-to-face ergonomically designed seats with full four-point harness seat belts. There is a personal weapons storage area, mission equipment storage, a radio suite intercom and a split air-conditioning system to each occupant seat position.

The cabin is fitted with three roof hatches with locking handles to provide protection against ambush and an alternative escape route.

The vehicle is transportable in C-130 Hercules aircraft for rapid deployment in forward areas of operation.

In June 2008, Thales launched a single-cab utility variant, the Bushmaster single cab armoured combat support vehicle. This variant can carry 4,000kg load on its rear tray, and has a cruising speed of 100km/h and maximum range of 800km.

In 2009, an additional variant was added to the range, which includes a dual cab that has been down selected for the UK MoD’s operational utility vehicle systems (OUVS) requirement.

The Bushmaster family of vehicles is available in a range of variants, including troop transport, ambulance, direct fire, mortar, engineer and command for application in combat and combat support roles. It is capable of sharing a high level on commonality, reducing the training and logistics footprint.

Driver’s cabin

The driver and crew cabin areas are ergonomically designed for comfortable travel in varied terrain and harsh environments, minimising crew fatigue and allowing the crew to rest or concentrate on the mission. The engine noise level inside the cabin and crew compartment is very low.

The cabin is fitted with a large windscreen and side windows for all-round visibility. The dashboard is ergonomically arranged, with easily readable and night-vision goggle compatible cockpit instrumentation.

The driver can use the push-button control central tyre inflation system to adjust the tyre pressure while on the move to suit the terrain type and keep the tyres inflated with limited punctures.

Bushmaster weapons

The forward central roof hatch can be equipped with a weapon mount for a 5.56mm or 12.7mm machine gun. A light cannon can also be fitted. The ballistically protected windows can be fitted with optional shooting ports.

Lockers can be replaced with additional ammunition and arms or fuel and water tanks to extend the operational radius. The crew seating can be reconfigured to accommodate operational requirements.

Propulsion

The Bushmaster engine, a Caterpillar 3126E ATAAC turbocharged six-cylinder, produces up to 224kW (300hp) at 2,400rpm. It provides a power to weight ratio of 16kW/t, governed maximum cruise speed of 100km/h. The vehicle has a range of more than 800km.

A double wishbone independent suspension system designed by Timoney in County Meath, Ireland provides good cross-country mobility across difficult terrains. The complete powerpack, (engine, automatic transmission, cooling system) can be easily replaced in the field without special tools.

Self-protection

The armour-protected monocoque protects against the blast of claymore, anti-tank mines, anti-personnel mines, mortars, improvised explosive devices and has a range of ballistic protection kits. The shaped hull deflects the blast.

Wire cutters are installed on the roof on both sides of the vehicle to protect soldiers exposed above the roofline. The fuel and hydraulic tanks are located outside the crew compartments to minimise fire risk.

A 270l drinking-water tank is installed under the floor of the crew compartment, contributing to crew safety in the event of a landmine explosion. The armour protected seating provides additional protection against spinal injuries.

Global Armoured and Counter-IED Vehicles Market 2011-2021

This project forms part of our recent analysis and forecasts of the global armoured and counter-IED vehicles market available from our business information platform Strategic Defence Intelligence. For more information click here or contact us: EMEA: +44 20 7936 6783; Americas: +1 415 439 4914; Asia Pacific: +61 2 9947 9709 or via email.

.gif)