Bayraktar is a mini UAV produced by Baykar Makina for the Turkish Armed Forces. Designed for short range reconnaissance and surveillance missions, Bayraktar is currently operational with the Turkish Land Forces.

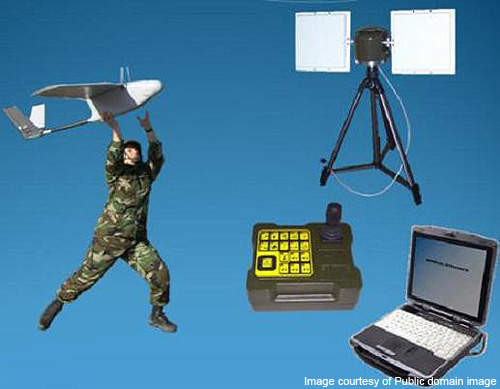

The mini UAV was developed by a joint venture of Baykar Makina and the Kale Group. The hand-launched, fully autonomous UAV took in to the skies first in October 2005. The Bayraktar fleet has completed more than 20,000 flight hours.

In August 2006, the Turkish Army placed a contract with Kale-Baykar joint venture for the delivery of 19 Bayraktar hand-launched mini UAV systems.

The first acceptance tests of the UAV systems were successfully completed and the prototype aircraft delivered in December 2007. The flight demonstrations were concluded in 2009 and the UAV was accepted by the Turkish Land Forces Command in 2010.

Bayraktar UAV design

The fuselage components are made of composites including carbon fibre and glass fibre, Kevlar, foam and epoxy materials. The front section houses modular payloads such as a thermal camera module or day camera module, which can be installed pre-flight.

The wing assembly consists of the right wing, middle wing and left wing. The V-Tails are equippeded to the tail boom, which is connected to the main fuselage. The main fuselage is mostly covered with a Kevlar laminate to absorb the shock of belly landing. The main structural parts of the UAV are interchangeable. The UAV is driven by an electric motor powered by battery.

Bayraktar features a unique parachute system for the recovery. The parachute system enables the UAV to land on areas with restricted flatness. The UAV however has automatic belly landing feature too.

Payload

The Bayraktar mini UAV was tested and demonstrated with electro-optical / infra-red payload. It can be configured for carrying either thermal camera (Payload 1) or day camera (Payload 2).

Navigation

The Bayraktar mini UAV can be controlled either manually from the ground control station or through autopilot system. Equipped with advanced software algorithms, the autopilot system enables the mini UAV to be used as a reliable flying platform for reconnaissance missions. The UAV system uses frequency-hopping spread spectrum (FHSS) digital data link for the data transfers.

The UAV can autonomously perform taxi, takeoff and landing operations with the help of onboard sensors. It can automatically return home and land safely in case of lost communication; hence useful in GPS-denied environments. The UAV is also equipped with stall and spin control mechanism for safe flight operations.

Ground control station

The portable ground control station (GCS) retrieves, processes and stores the real-time data provided by the mini UAV. The portable GCS features a rugged touch screen laptop / PC for mission planning / control and payload control / image review.

The control screen is used for displaying the flight status data as well as switching the UAV from manual to automatic mode. The GCS operator controls the payloads and sensors while gathering information from the battlefield.

The control station is also fitted with a real-time micro-controller based system, membrane button panel, industrial joystick, power supply and rechargeable battery unit (three hours working time). The GCS requires two crew members to operate the UAV.

Performance

Bayraktar has a length of 1.2m and a wingspan of 2m. The maximum take-off weight of the UAV is 4.5kg. The stated endurance is 60-80 minutes. The UAV can fly at an operational altitude of 4,000m. It has a cruise speed of 60km/h and a maximum range of 150km. It can fly in temperatures ranging from -20°C to +55°C.

The Global Unmanned Aerial Vehicles (UAV) Market 2011-2021

This project forms part of our recent analysis and forecasts of the global unmanned aerial vehicles (UAV) market available from our business information platform Strategic Defence Intelligence. For more information click here or contact us: EMEA: +44 20 7936 6783; Americas: +1 415 439 4914; Asia Pacific: +61 2 9947 9709 or via email.