BAE Systems’s FAST Labs research and development organisation has been awarded a US Defense Advanced Research Projects Agency (DARPA) contract for the technologies for heat removal in microelectronics at the device scale (THREADS) programme.

THREADS aims to overcome the temperature limits at the transistor scale inherent to power-amplifying functions.

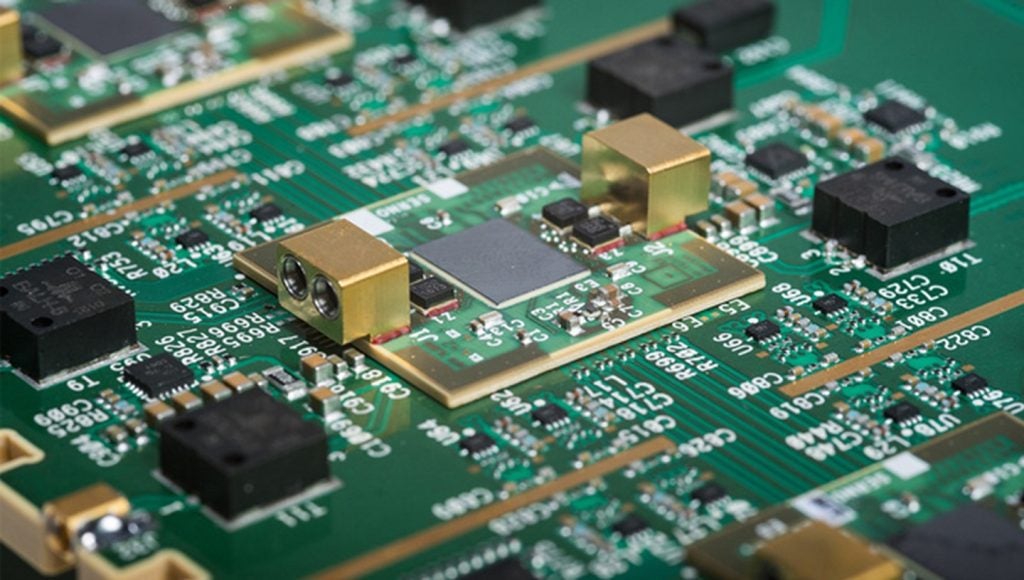

With new materials and approaches to diffusing the heat that degrades performance and mission life for monolithic microwave integrated circuits, it is believed that THREADS will resolve the thermal management challenges of today’s gallium nitride (GaN) devices.

Many military systems leverage radio frequency (RF) electronics and have historically operated at powers well below their theoretical limits because the GaN transistors get too hot.

Solving this challenge will improve the range of RF-based systems by nearly threefold, the new contractor says. This will expand engagement distances for users.

BAE Systems will leverage its expertise and track record of developing and manufacturing advanced microelectronics for the programme at its facility in Nashua, New Hampshire. The site is an accredited US Department of Defense (DoD) Category 1A trusted Supplier and manufactures GaN and gallium arsenide integrated circuits in production quantities for critical DoD programmes.

DARPA already has a well-established basis for microelectronics survivability when it comes to heat. Its Advanced Sources for Single-event Effects Radiation Testing (ASSERT) programme is focused on assuring that advanced US microelectronic components can operate in harsh radiation environments with the highest possible reliability.

To facilitate the development of optimally radiation-hardened components, as well as rapidly deliver cutting-edge tech to the user, ASSERT seeks to disrupt the status quo in rad-hard design and qualification by integrating radiation testing throughout the design and development life cycle.