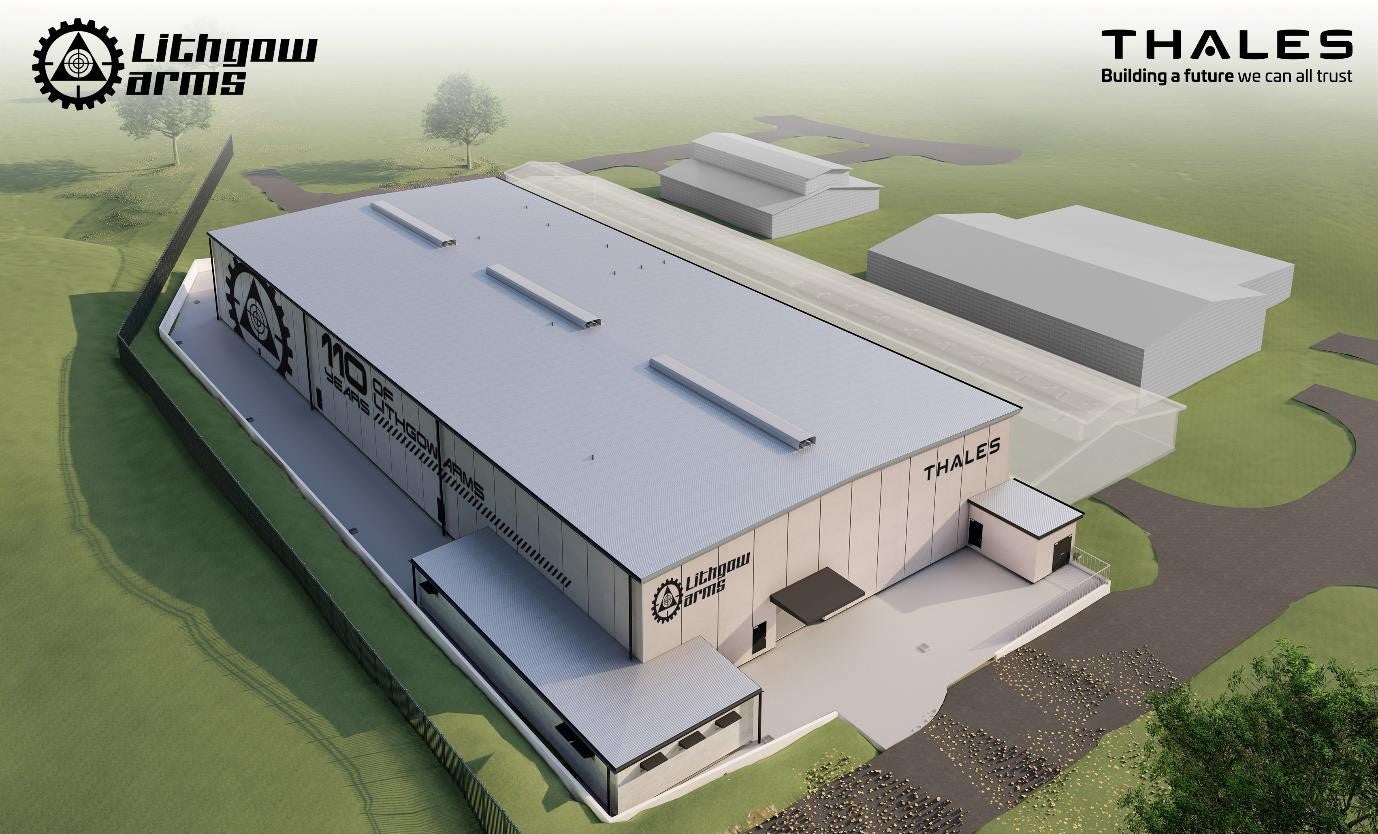

Thales Australia has revealed plans to invest $6.5m to expand the precision manufacturing capability of the Lithgow Arms facility in New South Wales (NSW), Australia.

The investment in the first phase of an industrial plan aims to redevelop the facility, which has been producing small arms for Australian soldiers.

The first phase of the new development will see the integration of traditional precision manufacturing and digital technologies.

It covers installation of capabilities such as 3D printing, automated electro-plating and other technologies related to metal treatment.

Furthermore, the development will include a new purpose-built live firing test and evaluation capability aimed at supporting systems integration.

This capability will also advance the development of digitised weapon system platforms and small arms.

Thales Australia & New Zealand Land vice-president Corry Roberts said: “Lithgow has been the home of small arms manufacturing for over a century.

“Transforming Australia’s manufacturing capability benefits Australia’s self-reliance and evolves the capability of the broader Australian advanced manufacturing sector, which is essential in growing local jobs, and delivering advanced capability advantage to the Australian Defence Force.”

The industrial plan seeks to convert Lithgow Arms facility into a new hub that develops, and precision manufactures next-generation soldier weapons systems for the future Australian Defence Force.

In July 2019, Thales invested in a new honing machine on Lithgow Arms’ rifle production line.

Thales Integrated Weapons and Sensors director Graham Evenden said: “It’s a real privilege to see our design team push the boundaries of traditional small arms solutions.

“Our future systems include automated and augmented features enabled by modern networked sensors and sovereign artificial intelligence while the system architecture is being developed to support integration with next generation soldier systems.

“Our industrial plan is designed to support the manufacture, maintenance and upgrade of our future systems and seeing this first phase come to life is very rewarding for our Lithgow teams.”