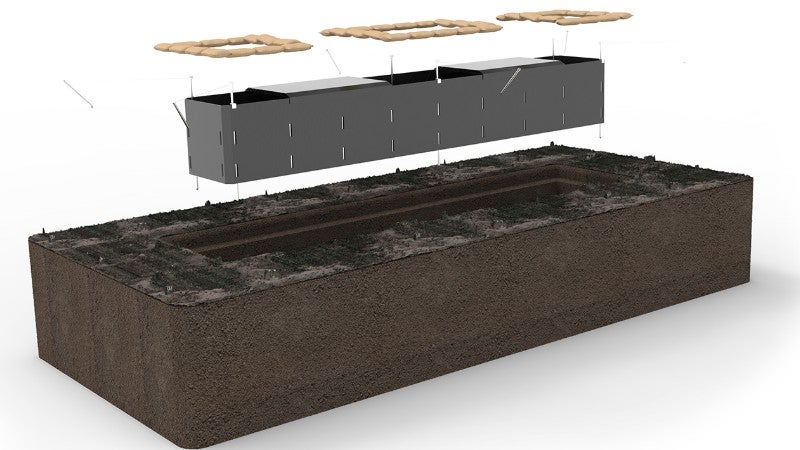

Williams Advanced Engineering is developing 3D lightweight military shelters for troops, using innovative composite technology derived from Formula One (F1).

The engineering company is working in collaboration with the UK Defence Science and Technology Laboratory (Dstl) and the Defence and Security Accelerator (DASA) to speed up delivery of the protective, yet lightweight military shelters.

Williams Advanced Engineering managing director Craig Wilson said: “Lightweighting is a key principle of motorsport and the use of carbon fibre has been crucial to the ongoing development of racing and on into more mainstream applications.

“To think that innovations from the team here at Williams Advanced Engineering can deliver enhanced, lighter protection for the armed forces is a great feeling for us. We look forward to working with Dstl and DASA to enable deployment of our technology by service personnel for their protection.”

The F1 composite technology employs fibre-reinforced polymer, namely glass fibre, carbon fibre, aramid and IR absorbing materials.

They can offer varying levels of requirement-specific protection based on the molecular structure of the composite material. For example, some could be adapted to be tougher while others will be more lightweight, depending on the mission requirement. Composite shelters can be modified to protect against blasts, fragmentation, ground shock, and even thermal detection.

The composite lightweight military shelters are much easier to carry than existing ones made from steel or alloys, but the cost of composite materials and issues with production tooling and ease of handling have restricted the use of composites to low-volume, high-performance applications.

However, DASA’s ‘Take Cover’ competition offers an opportunity for Williams to implement its composite technology and become a leader in delivering advanced composite materials for use by the UK Ministry of Defence.

“DASA was created to find and fund exploitable innovation for defence and security,” said DASA delivery lead Dr Adam Staines.

“Key for this mission is wider engagement with non-traditional suppliers across a range of industrial sectors. Accessing cutting-edge technology developed initially for F1 is a prime example of this engagement.

“Lightweight foldable materials which can be assembled quickly to provide protection for troops was a key aim of this DASA themed competition. In addition to protecting troops and saving lives on the battlefield this technology has potential uses for domestic security and humanitarian applications.”

Minimising the heavy burden of carrying equipment on the battlefield is essential for the army, as is the protection of troops – another area where F1 technology has been used.