The longitudinal and sheer energy waves produced by an earthquake travel through the ground and can destroy buildings miles from the epicentre. Preventing that damage requires a solution that can withstand these multidirectional waves travelling through a solid material but that is also flexible.

Enter metamaterials, a term for artificially constructed material, usually a composite, engineered in patterns that give them unique properties often to do with the way they manipulate waves.

Dr Guoliang Huang, a James C. Dowell Professor in the mechanical and aerospace engineering department at the University of Missouri’s College of Engineering leads a team that has developed a lattice-type material that protects against both types of wave and is flexible enough to wrap around the objects it is protecting – a building or vehicles, for example.

The US Army Research Office funds the research, which has clear defence applications, including protection against vibration in mechanical parts, such as aircraft or submarine engines, and flexible protection for soldiers and equipment against blast energy.

Two papers on the research, ‘Polar metamaterials: a new outlook on resonance for cloaking applications’ and ‘Physical realization of elastic cloaking with a polar material’, were published in Physical Review Letters, a journal of the American Physical Society. Here Huang tells us about the project, the material and its potential applications.

Berenice Baker: Could you tell us about the background to your research and how you came to research this metamaterial?

Dr Guoliang Huang: My work is in the broad research area of solid mechanics and architected materials. In particular, I study the new frontiers of structural dynamics and wave propagation. My recent research has focused on addressing challenges and applications in elastic and acoustic metamaterials for areas including efficient vibration-acoustic-seismic wave mitigation, structural health monitoring, energy harvesting and bio-sensing. One important application of my research is for earthquake mitigation to design wave-absorbing materials in very low frequencies.

What makes the your metamaterial useful for protecting against damaging vibrations?

The polar metamaterial is an ideal material for elastic wave cloaking. It is constructed by a lattice structure that can bend waves or vibrations so that objects inside the polar metamaterial coating are untouched by these waves or vibrations. Therefore, it is particularly useful for protecting against vibrations that might damage a structure.

How do you make and test it the material?

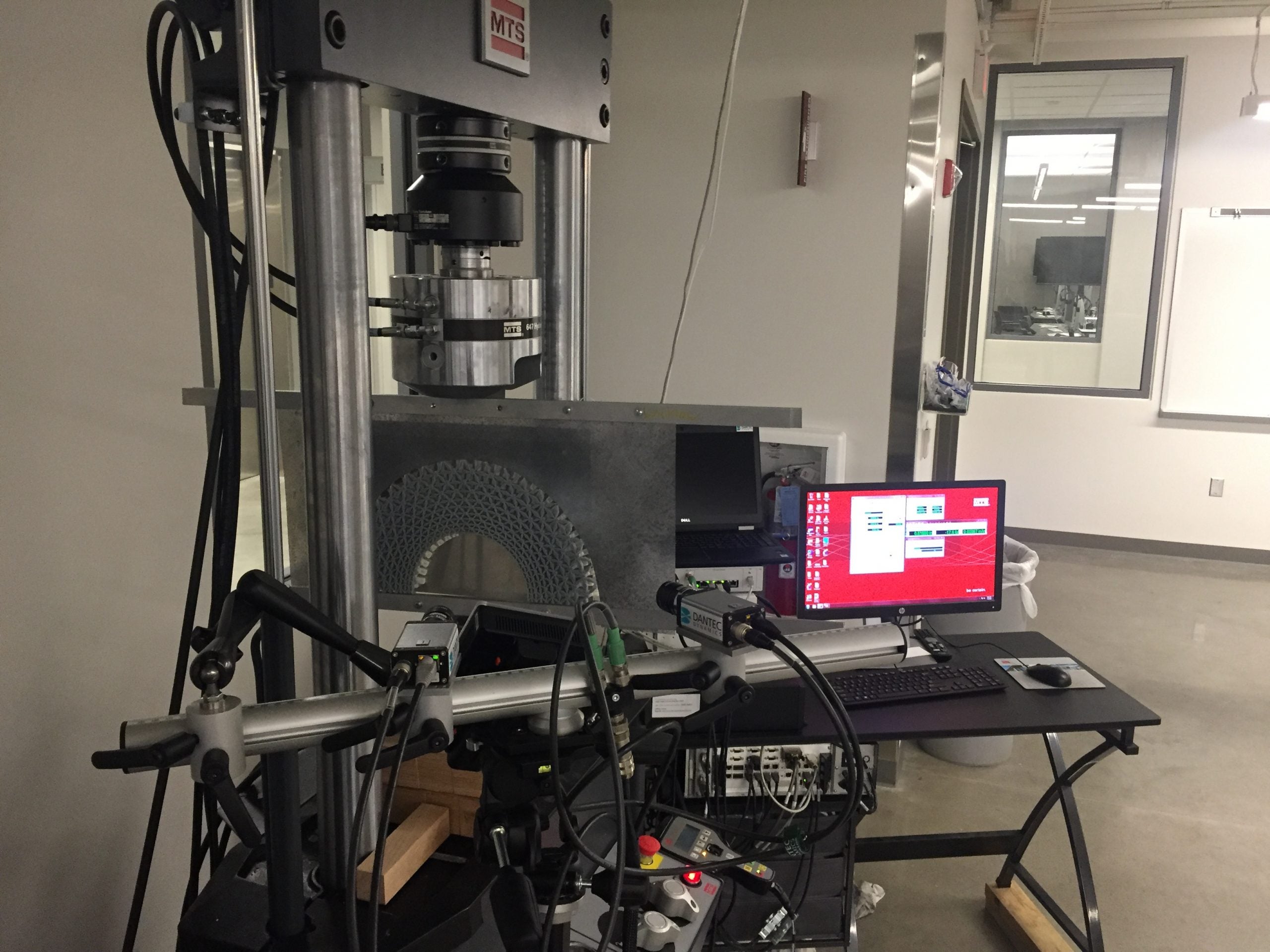

The polar metamaterial was fabricated by 3D printing. We performed static tests with tension and shear loadings. We are planning to do dynamic testing in the near future.

The Army Research Office is interested in the material’s ability to steer mechanical waves away from critical regions in solid objects. Could you tell us more about the potential military applications?

The polar metamaterial can also be used in communications, sensors and monitoring of a structure’s health through the use of information provided by sound and vibrations. The polar metamaterial can improve the performance of those aspects of the devices.

We are planning to find more military applications of the polar metamaterial, particularly in the fields of communications, sensing, imaging and structural health monitoring.

What is the biggest challenges in developing this material and what has most surprised you about it?

The biggest challenge of this project is to design the microstructure of this material with no known material properties. For over 20 years, no one had a natural solution for this issue in a solid material. The ultimate purpose of the proposed research is to model, design and fabricate materials that will fill in this ‘behavioural gap’.

The polar metamaterial for elastic cloaking should be collapsed under a certain stress state and, at the same time, produce torque when rotating, which is the most surprising phenomena.

What would you like people to know about lattice metamaterials?

There are many types of lattices that can be used for this purpose. Most of them have yet to be discovered. We believe researchers in this field will find more exciting applications in the near future.