TIAG Industries, a French company with a 40-year history in the plastic ammunition container sector, has won Innovation award for Ammunition Packaging in the 2024 Army Technology Excellence Awards.

The Army Technology Excellence Awards celebrate the greatest achievements and innovations in the industry. Powered by GlobalData’s business intelligence, the Awards recognize the people and companies that are driving change in the industry.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

TIAG Industries earned the Innovation award for their pioneering design of a standard blowmolded 120mm mortar container, which enhances ammunition packaging through its lightweight, durable construction, smart stacking system for improved storage, and commitment to sustainability with 100% recyclable materials, all while adhering to strict safety standards.

Enhancing military logistics with lightweight ammunition containers

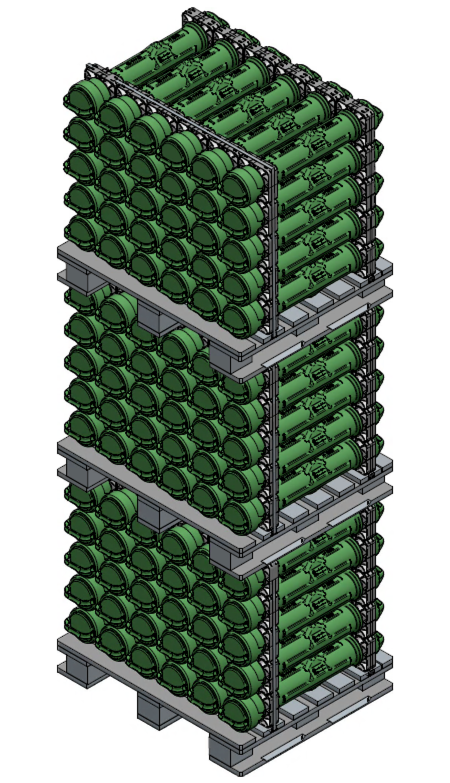

The logistical challenges of military operations are numerous, with the need to move equipment quickly and efficiently being paramount. TIAG Industries has innovated in this space by developing the first standard blowmolded container for 120mm mortars. This design significantly enhances the efficiency of ammunition packaging by providing a lightweight solution that does not compromise on strength or durability.

The containers, made from High-Density Polyethylene (HDPE), are at least 30% lighter than traditional steel alternatives, with an empty weight of 4 kilograms. The reduction in weight eases handling and transport, allowing for swift deployment and maneuverability. The lightweight also means that more ammunition can be transported in a single load, reducing the number of trips required and thereby enhancing operational efficiency. Furthermore, the ease of handling reduces the physical strain on military personnel, potentially decreasing the risk of injury and fatigue during operations.

Smart storage solutions for improved ammunition accessibility

Efficient storage solutions are essential for maintaining the high readiness levels required by military forces. TIAG’s new individual stacking system is a significant improvement over traditional storage methods. The system allows for the selective removal of containers, meaning that units can access the exact ammunition they need without the time-consuming process of unloading entire pallets. The design includes two-sided grips and a compact size, enabling single-person handling, which contributes to operational speed.

The innovative stacking system not only maximizes space utilization within storage facilities, but also ensures that ammunition is readily accessible, even under the most demanding conditions. It is particularly beneficial in forward-operating bases where space is at a premium and rapid response times are crucial. The system also simplifies inventory management, making it easier to track ammunition usage and replenishment needs.

Commitment to sustainability and safety

TIAG’s new ammunition packaging is produced from 100% recyclable materials, and the production process is zero-waste, with all scraps immediately reinjected during the production cycle. This not only minimizes environmental impact but also reduces material costs, contributing to the overall cost-effectiveness of the solution. Additionally, the containers meet stringent safety standards, as evidenced by their UN Homologation. This certification confirms the container’s compliance with rigorous safety protocols, ensuring secure protection of ammunition across various environmental conditions, including extreme temperatures ranging from -46°C to +71°C.

The HDPE material used in the containers provides unique shock-absorbing properties and high chemical inertness, making it suitable for the transport of highly dangerous goods. The containers’ water and airtight seals further ensure the integrity of the ammunition, protecting it from moisture, dust, and other environmental contaminants.

By focusing on operational efficiency, cost-effectiveness, and environmental responsibility, TIAG Industries has shown that high-quality, safe, and sustainable solutions are achievable in military logistics. The award-winning 120mm mortar container exemplifies TIAG’s expertise and commitment to excellence, providing a model for future advancements in defence technology.

“It is an honour to receive this award, which is the result of the work of an entire team. This motivates us to continue investing in development processes, allowing us to propose innovative solutions to our land armament partners.”

Alexandre Moraine, CEO, TIAG Industries

Company Profile

TIAG Industries is a French company founded more than 30 years ago. TIAG is specialized in the fabrication of technical plastic parts through three production processes: injection, blowmolding, and rotomolding. TIAG began its journey by designing and producing plastic containers for major European land armament partners, later diversifying its business areas. This allowed the company to become one of the European leaders in plastic transformation for hospital equipment. TIAG also works for other sectors such as agriculture and construction machines, energies, and public services.

TIAG Industries, it is now 130 employees dedicated not only to reactivity and continuous improvement for its clients, but also to security of the staff.

Links

Website: https://www.tiag-industries.com/