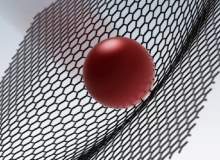

The Rice University team conducted miniature ballistic tests by firing microscopic projectiles at sheets of graphene, each consisting of a single layer of carbon atoms arranged in a honeycomb structure.

Using the energy from a laser to drive microbullets at great speed from the opposite side of an absorbing gold surface, the laser-induced projectile impact test (LIPIT) evaluated graphene sheets ranging from 10nm to 100nm thick.

A high-speed camera was used to capture images of the projectiles before and after hits, to judge their speed and microscope images of the damage to the sheets.

In each case, the 3.7-micron spheres punctured the grapheme, but left a fractured pattern of ‘petals’ around the point of impact rather than a neat hole, indicating that graphene stretched before breaking.

The experiments confirmed that graphene works as a stretchy membrane to distribute the stress of the bullet over a wide area defined by a shallow cone centred at the point of impact, in about three nanoseconds before puncture.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataWhile tensile stress cannot travel faster than the speed of sound in materials, in graphene it was found to be much faster than the speed of sound in air, which is 1,125ft/sec.

Rice University George R. Brown School of Engineering William and Stephanie Sick Dean, Edwin Thomas, said: "For graphene, we calculated the speed at 22.2km per second, which is higher than any other known material. The game in protection is getting the stress to distribute over a large area.We’re working to demonstrate to NASA and the military that these microscopic tests are relevant to macroscopic properties."

Supported by the US Defense Threat Reduction Agency and the Welch Foundation, the research indicated that controlled layering of graphene sheets could lead to lightweight, energy-absorbing materials.

Follow Berenice Baker on Google+

.gif)